Electric motors are vital components of all types of battery-powered vehicles. However, EV motors traditionally require magnets and rare-earth materials, such as neodymium and niobium. To address the issue, engineers are scrambling to develop new designs that offer increased efficiency and reliability, in addition to reduced cost and noise.

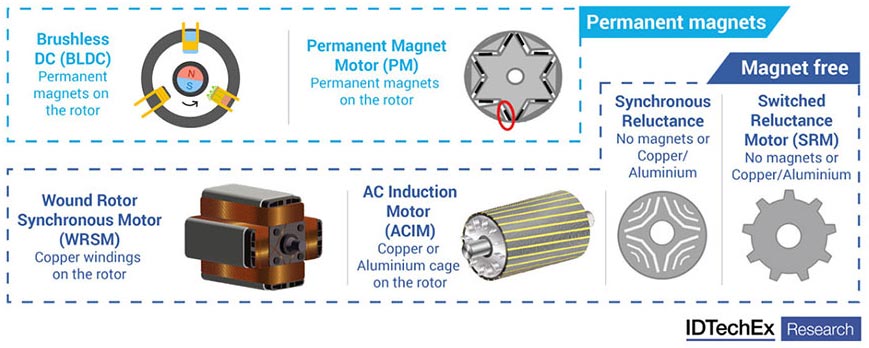

In 2022, 82 percent of the electric car market globally was using rare earth based permanent magnet motors. Magnet-free alternatives include switched reluctance motors and wound rotor synchronous motors.

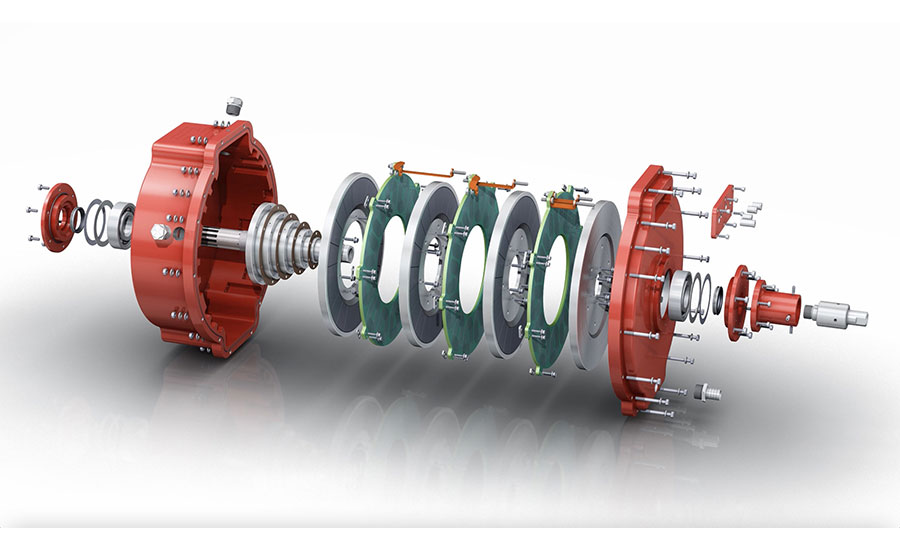

Earlier this year, at the Consumer Electronics Show in Las Vegas, Infinitum debuted a new design called the Aircore Mobility motor. The next-generation axial flux traction device is designed to power a variety of electric vehicles. Besides cars and trucks, the technology can also be used for agricultural, aviation, construction and marine applications.

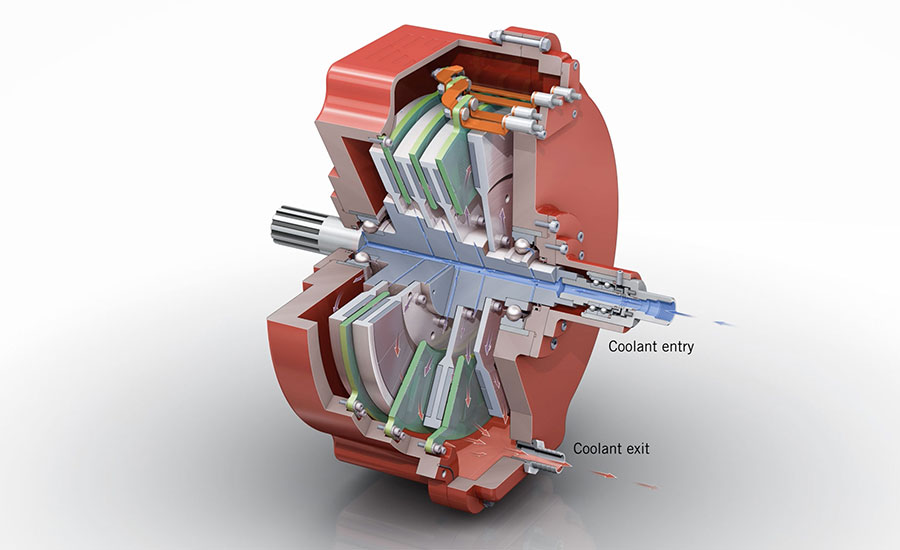

Delivering high power and torque density, the Aircore Mobility motor operates over a wide range of speeds and loads. At the heart of the technology is a lightweight printed circuit board (PCB) that replaces copper-wound iron stators found in traditional motors. As a result, noise, vibration and harshness (NVH) and mechanical losses are reduced, while efficiency is improved.

According to Infinitum, compared to conventional devices, the Aircore Mobility motor is 10 percent more efficient, half the size and uses 66 percent less copper. Meanwhile, thanks to the PCB stator design, the motor can achieve up to five times the density of a conventional liquid-cooled motor.

A liquid cooling process enables coolant to come into direct contact with the stator, which mitigates heat across a larger surface area. As a result, there’s a higher overload capacity and product life is extended.

“Our motor topology eliminates core losses and delivers a broader range of speeds and load conditions where the motor can operate at high efficiency levels,” says Paulo Guedes-Pinto, vice president of technology at Infinitum. “[It] offers a new avenue in extending range for Class 1-8 vehicles, aerospace, marine, construction and agricultural machines.”

Infinitum knows the challenges ahead when it comes to mass-producing motors, but it claims that it’s prepared for the task.

“Our planet adds 800 million motors each year and their demand continues to grow rapidly as the world electrifies,” explains Rick Tewell, president of Infinitum. “We’ve combined class-leading performance with sustainability by reimagining the motor’s century-old design and construction to meet the needs of the next generation.

“Our highly efficient motor…can be manufactured with fewer raw materials and assembled rapidly due to its unique modular design,” claims Tewell. “This same design facilitates maintenance and allows housings, rotors and stators to be reused in motors that are remanufactured to serve future generations.”

Reducing energy consumption, carbon emissions and waste are becoming high priorities for EV manufacturers searching for sustainable propulsion alternatives.

“Our current focus is on scaling and accelerating the mass production of our sustainable motors to meet demand,” says Tewell. “Our motors are [already] having a dramatic and positive impact in the HVAC air handling market, where they have become a key ingredient for reducing energy demand in commercial buildings, large data centers and industrial applications.”

This next-generation axial flux traction motor delivers high power and torque density, while operat-ing over a wide range of speeds and loads. Illustration courtesy Infinitum

The Aircore Mobility motor enables coolant to come into direct contact with the stator, which miti-gates heat across a larger surface area. Illustration courtesy Infinitum

A Wonder Down Under

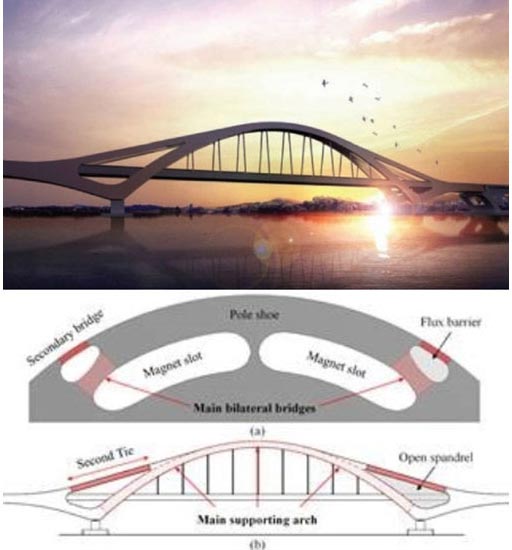

Engineers at the University of New South Wales (UNSW) in Sydney, Australia, recently developed a motor that was inspired by the contours of South Korea’s longest railroad bridge. The Gyopo bridge is a double-tied arch structure that uses a compound-curve-based mechanical stress distribution technique.

The Gyopo rail bridge, a double-tied arch structure that uses a compound-curve-based mechanical stress distribution technique, inspired the development of a new type of motor. Illustration courtesy the University of New South Wales

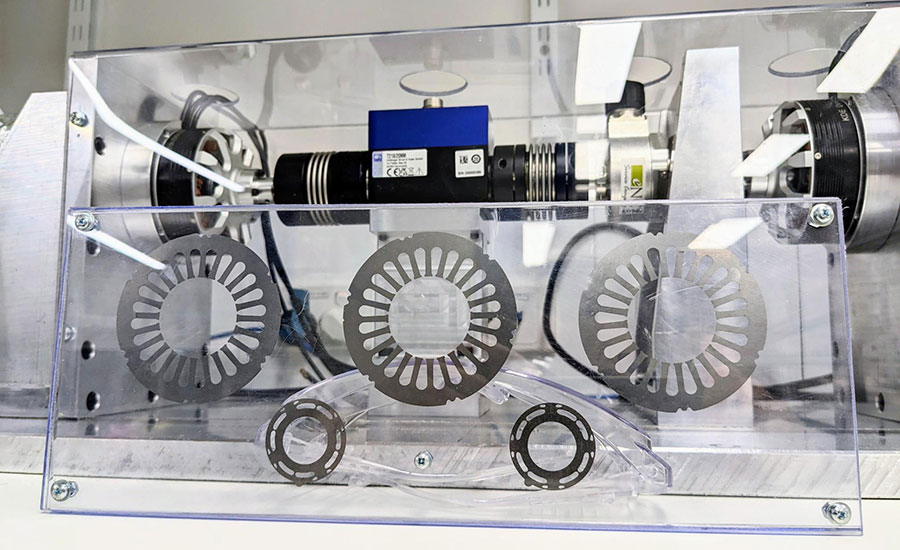

A prototype motor achieved speeds of up to 100,000 rpm. That power exceeds the existing record of similar interior permanent magnet synchronous motor units.

“By implementing cross-disciplinary design and genetic algorithm-based motor design optimization, the high-speed motor has successfully exceeded the state-of-art metric of interior permanent magnet motors and doubled its speed,” says Rukmi Dutta, Ph.D., an associate professor of electrical engineering at UNSW.

“Most importantly, the high-speed and novel rotor design allows the [motor] to achieve high efficiency and a very high specific power density (7 kilowatts per kilogram) with reduced rare-earth magnets,” claims Dutta. “The high power density is extremely favorable for weight-sensitive applications, such as electric vehicles.”

“Micro gas turbines proposed for hydrogen [energy systems] and flywheel systems as mechanical batteries for…power grids…can also benefit from our high-speed machine,” Dutta points out.

The use of reduced rare-earth magnets means less critical material consumption, lower cost and a more secure supply chain. In the near future, Dutta and her colleagues plan to explore whether rare-earth magnets can be eliminated completely without compromising performance gains and power density.

“So far, we have successfully built collaborations with industry partners from the e-turbo charger, HVAC and e-mobility sectors,” explains Dutta. “We have secured funding from government, industry and academic institutes to further develop and commercialize the technology. We have also attracted interest from companies [that want to invest in] the technology.”

Novel rotor and stator designs enable high-speeds. Photo courtesy the University of New South Wales

Precious Material Management

Obtaining raw materials to produce electric motors results in environmental damage and is subject to supply-demand imbalances, supply chain management issues and increasing cost pressures. That’s why Tula Technology Inc. has been developing alternatives to rare-earth magnets since 2021.

“The EV industry covets the highest possible efficiency,” says Scott Bailey, CEO of Tula. “At the same time, the critical challenges associated with the need for rare-earth magnets in interior permanent magnet (IPM) motors—environmental impact of mining, limited supply, which is driving up cost and an insecure source of supply—can no longer be ignored.

“As a result, most companies are looking for alternatives to IPM motors that are lower in cost, while not sacrificing efficiency,” explains Bailey. “Externally excited synchronous motors (EESM) are the leading candidate.”

Automakers such as BMW and Renault are leading the charge. However, Bailey claims that much of the industry is either planning on or evaluating the technology. “Fortunately, this is where our dynamic motor drive (DMD) technology has the greatest impact,” he points out.

“Optimized EESM with [our] DMD controls will reduce losses by up to 19 percent, which translates into a 3 percent efficiency gain on the EPA’s multi-cycle test,” says Bailey. “More importantly, the combination of EESM and DMD delivers better efficiency than IPM motors, and at $150 to $200 less cost at a system level.

“We strive to gain maximum efficiency without negatively impacting NVH or drive quality,” notes Bailey. “Given the quiet, smooth operation of EVs, this is critical.

“We have successfully demonstrated the capability of DMD on IPM vehicles and, while the gains are modest (0.4 percent), we have proven that our innovative controls work flawlessly and produce the advertised efficiency gains,” claims Bailey.

Tula is currently building an EESM-equipped Tesla Model 3 demonstrator to showcase the full capability of DMD. The vehicle should be available for testing by early next year.

A key development for Tula is the work going into new EESM designs. These machines require wire wound rotors (as opposed to a stack of metal laminations with magnets), and EESMs are often referred to as wound rotor machines. However, from an assembly standpoint, EESMs are a bit more complex.

“In an IPM, metal laminations are typically stamped in production and then stacked for assembly with permanent magnets onto the rotor shaft,” explains Bailey. “EESM or wound rotor designs also require a stack of metal laminations, though with a much different profile than IPM.”

Several EV motor technologies can avoid the use of permanent magnets. Illustration courtesy IDTechEx

“Instead of pressing magnets into the laminations, wire coils are wrapped around some number of poles that are inherent in the design of the rotor stack,” adds Bailey. “While this is a bit simplistic, wound rotor machines have essentially replaced permanent magnets with copper wire. The transition to EESM will impact production and assembly processes.”

Fortunately, suppliers such as Marsilli have a history of winding copper wires and have developed some very innovative processes optimized for EESM production.

“Going forward from a development standpoint, completing our work on the Tesla EESM demonstrator vehicle is at the top of the list,” says Bailey. “While customers appreciate our test data from motor dynamometers and IPM vehicle demonstrators, we also need to be able to demonstrate EESM drive performance in a vehicle and provide independent lab test results that confirm our projected efficiency gains.

“Given the pace of change in the industry, we are focused on moving incredibly quickly to deploy DMD on a global basis,” says Bailey. “This progress requires money, resources and global reach. To address this need, we are currently raising additional funding for our DMD business, with a keen focus on strategic investors that can also become business partners and help accelerate our growth.”

Old Dogs With New Tricks

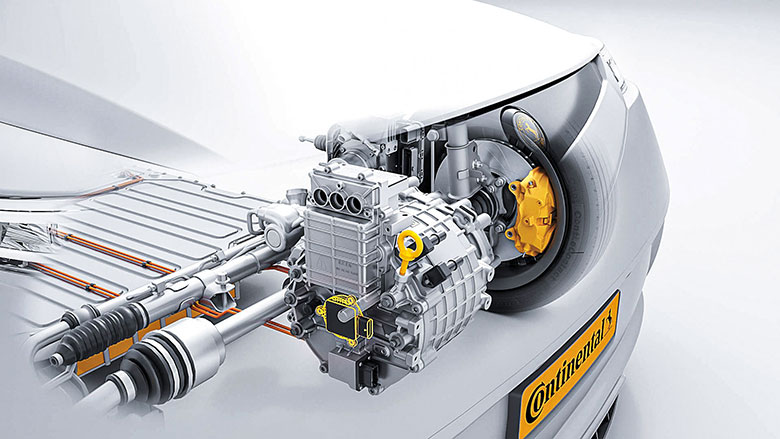

While the dawn of the EV era has seen many start-ups enter the automotive industry, many legacy Tier 1 suppliers are developing new products. For instance, Continental AG recently introduced an electric motor sensor that that can help increase efficiency and produce smoother operations.

The e-motor rotor position sensor (eRPS) is more compact and 40 percent lighter than conventional devices. It will be commercially available in late 2025.

“The growth in vehicle electrification translates into more synchronous motors in the car,” says Laurent Fabre, head of the passive safety and sensorics segment at Continental. “This ranges from big and powerful ones like traction motors to smaller ones like electric pumps. Our standardized eRPS technology has a wide range of potential applications in electric vehicles.”

This motor achieves high efficiency and high power density with reduced rare-earth magnets. Photo courtesy the University of New South Wales

Meanwhile, Siemens AG has effectively spun off its motors and large drives business in Germany under the new name of Innomotics. The supplier of motors and large drives will bring together business activities with low- to high-voltage motors, geared motors, medium-voltage converters and motor spindles.

The separation in Germany has been completed and Innomotics expects the global operations transition to be finished by next month. In the future, Innomotics will comprise the corresponding businesses from Siemens’ large drive applications and digital industries, as well as the separately managed Siemens companies Sykatec and Weiss Spindeltechnologie.

“Our new brand stands for our aspiration of being a leading innovator in the motor and large-drive business, and expresses the way we view ourselves as a company that maintains close customer proximity and has more than 150 years of history,” says Michael Reichle, CEO of Innomotics.

“With highly efficient, electric large-drive systems, we can replace conventional systems that are less sustainable,” explains Reichle. “In this way, we can then help our customers reduce their greenhouse gas emissions, especially in areas where very high levels of carbon emissions are still being generated today.”