Divergent Technologies, known for its comprehensive digital industrial production system, announced the successful completion of a $230 million Series D equity financing round. The financing was spearheaded by a substantial $100 million investment from Hexagon AB and saw participation from a mix of new and existing institutional and family office investors.

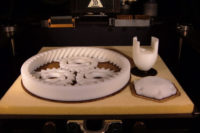

This latest funding round is a major vote of confidence for the Divergent Adaptive Production System (DAPS), a system-level replacement for conventional design, manufacturing, and assembly methods. DAPS integrates a holistic suite of tools encompassing AI-driven generative design software, novel materials, 3D printing, and automated fixtureless assembly for creating large multi-part systems.

Lukas Czinger, President and Chief Operating Officer added, “DAPS allows customers to develop higher performing products on faster timelines and with zero design-specific capex, freeing manufacturers from the burdens of legacy design decisions. Divergent is on a mission to rebuild the American industrial base with a truly transformational manufacturing technology.”

While DAPS was first showcased for its ability to design, 3D print, and assemble hypercars, Divergent has since moved into areas like defense and aerospace. The company boasts a roster of seven major automotive clients, including prestigious names like Aston Martin and Mercedes-AMG. In the aerospace and defense sectors, Divergent collaborates with six U.S. government contractors, such as General Atomic Aeronautical Systems Inc. (GA-ASI).

In fact, at this year’s Additive Manufacturing Users Group Conference, Divergent CTO Michael Kenworthy, revealed a project dedicated to designing, 3D printing, and robotically assembling a small drone for GA-ASI using industrial arms and specialty adhesive. As Divergent furthered its relationship with the defense giant, the firm appointed General Peter Pace, a retired chairman of the US Joint Chiefs of Staff, to its board of directors.

It’s worth noting that it was announced in December 2022 that Hexagon invested $100 million in Divergent, signifying the Swiss tech giant’s major interest and influence in the company. Naturally, then, we can assume that its design and engineering software is being used in the DAPS workflow. Because Hexagon offers tools for nearly every stage of production, we might infer that it is used at every stage of DAPS in some regard.

Additionally, Divergent recently acquired the in-process quality assurance (IPQA) technology of Sigma Additive Solutions, which includes monitoring for metal laser powder bed fusion (LPBF) machines. Given Divergent’s pioneering of the 12-laser LPBF machine from Nikon SLM Solutions, it’s possible to imagine that Hexagon has some stakes in the quality control aspect of the DAPS workflow.

“DAPS was created to serve as the foundation for a global system of regional manufacturing facilities that combine and fully exploit supercomputing, AI, robotics and additive manufacturing in a novel way,” said Kevin Czinger, Founder, Lead Inventor and CEO. “We now have entered the ‘4D Age’ of fully digitized design-manufacturing-assembly as a service, dematerialized products using and requiring less material and energy, distributed regional production, and democratized access to the tools, data and production assets necessary for innovation in our human-built world.”

Divergent’s unique and advanced technology is likely to herald a new era of manufacturing, particularly as governments and corporations attempt to near/friend/reshore their operations. Hexagon is clearly making an important bet in the space. As Divergent scales up and establishes microfactories globally, it will be interesting to see not only how it grows, but how Hexagon’s technology is applied in other digital manufacturing environments.

.jpg?1700072082)