WÖRTH, Germany—Electric trucks produced at the Mercedes-Benz assembly plant here are now being used to deliver parts to the factory.

Mercedes is providing its logistics partners with 20 battery-electric eActros 300s to deliver parts to the factory, which celebrated its 60th anniversary in 2023. The first 12 trucks were handed over Dec. 4; an additional eight trucks will be delivered in early 2024. The trucks will make approximately 50 runs to the plant each day.

The project to electrify inbound logistics to the Wörth factory was funded by a 3 million euro grant from the Federal Ministry for Digital and Transport.

“Electric trucks can already cover the majority of delivery routes over short and medium distances,” says Karin Rådström, CEO Mercedes-Benz Trucks. “We want to leave the smallest possible carbon footprint across the entire value chain.”

“I am pleased [that our funding] is helping to bring climate-friendly commercial vehicles onto the roads,” adds Michael Theurer, parliamentary state secretary to the Federal Minister for Digital and Transport. “With the implementation of emission-free deliveries to the Wörth plant, Daimler Truck is sending a clear signal: E-mobility can work well on a large scale and with heavy commercial vehicles.”

A key part of the project was the development of charging infrastructure at the Wörth site. After testing a pilot charging station over the summer, five additional charging stations will now be installed directly at various delivery areas within the plant. Two more charging stations will be installed in the truck parking lot in front of the plant gate by the end of the year.

All totaled, some 30 charging stations will be installed at various locations at the Wörth factory. The goal is to recharge the trucks while they are being unloaded. Ideally, the truck will be able to resume its route immediately after delivering parts. Charging stations are also being installed at each supplier’s location.

Based on its own experience, Mercedes-Benz Trucks is now offering a consulting service, called Electrified Logistics Accelerated, to help other manufacturers electrify deliveries at their factories.

“With the project to electrify logistics at Wörth, we have done real pioneering work together with our colleagues,” says Andreas Scharff, head of emobility sales and dealer network development at Mercedes-Benz Trucks. “It is now all the more important for us to share this expertise with other industrial companies and thus fuel the transformation to sustainable logistics.”

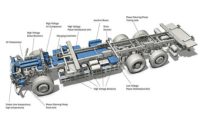

Designed for heavy transport, the eActros 300 has been rolling off the assembly line at Wörth since 2021. It is equipped with three battery packs, each of which has a capacity of 112 kilowatt-hours. It has a range of up to 330 kilometers without intermediate charging.