AUBURN HILLS, MI—As part of the company’s “We Win Together” initiative, a group of Stellantis engineers recently met with 64 suppliers and startups from around the world to learn about cutting-edge technology that can boost manufacturing productivity, reduce CO2 emissions, improve quality and cut costs.

The 8th annual Factory Booster Day was held in Betim, Brazil. Beginning as a bottom-up effort, Stellantis’ global manufacturing facilities identified 35 challenges that align to their strategic goals and the Dare Forward 2030 strategic plan. In a unique process, Stellantis shared these production challenges with current and potential future suppliers, including startup companies and universities, in an “open call,” asking for their best ideas.

In addition to the physical event, Stellantis manufacturing team members from around the world viewed presentations and demonstrations virtually through a metaverse platform. Plant managers who believe a solution can solve the challenge are empowered to launch a pilot test.

Some of the challenges presented at the 2023 Factory Booster Day included:

- How to improve process performance by leveraging artificial intelligence technology.

- How to model, measure and better manage energy consumption.

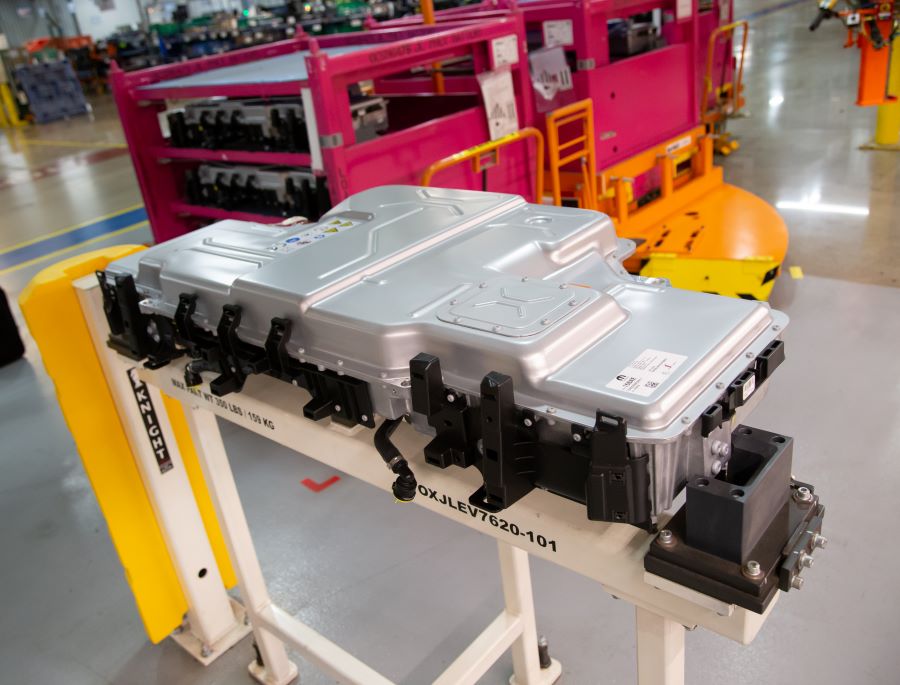

- How to detect loose material or contamination in an electric vehicle battery.

“In an automotive industry where disruption and opportunities are unlike any other time, we are building a strong community of actors that will bring innovative technologies and smart solutions to our facilities,” says Arnaud Deboeuf, chief manufacturing officer at Stellantis. “This great annual event allows us, together, to improve our efficiency and competitiveness, with our customers being the ultimate winner.”

Innovations previously adopted by Stellantis manufacturing plants include:

- High-tech welding of short flanges on vehicle doors, which delivered improvements in quality and stability of the welded part and less cost, compared with laser welding.

- An advanced computer vision system that can assemble parts on a moving assembly line. Computer algorithms enable tools to track any object. The system is easily integrated into an assembly line at minimal cost.

- Real-time energy use measurement and management with cloud-based analytics. The system proactively manages energy usage to meet targets and detects anomalies.