For wire harness assemblers, the key to profitability lies in the ability to produce harnesses at a competitive and well-understood cost. This is a difficult challenge, because project time scales and margins are continually squeezed, while variables such as design content and copper prices can change rapidly.

Engineers have several wire harness costing options available. Many small- and mid-sized harness shops rely on spreadsheets, which are inexpensive to purchase and run. They are readily available and familiar to millions of people.

Larger operations have attempted to automate the costing process by investing in custom-written software or off-the-shelf tools that accept design data directly, apply rules and parameters, and then calculate wire harness costs in minutes.

“I’ve been in a number of different wire harness shops over the years and seen a wide variation in the way that they get their costs,” says Rick Bromm, president of ALTEX Inc., which supplies custom products for manufacturers in a variety of industries, including agricultural and construction equipment, green energy, medical devices and rail transportation. “A lot of companies approach costing many different ways.

“Some companies simply take an educated guess on labor content,” notes Bromm. “We still rely on some good old-fashioned spreadsheets to do costing. But, we also use software programs that allow us to analyze variables such as raw materials and labor costs.”

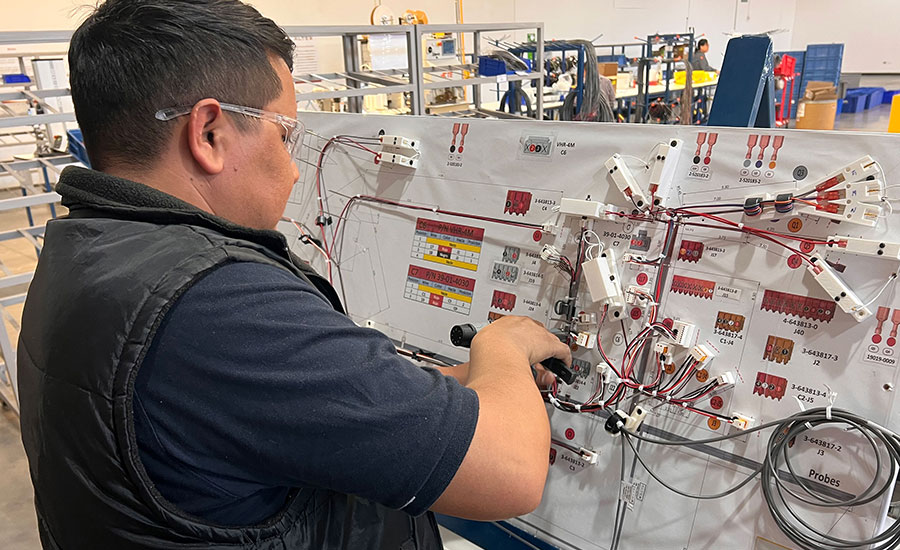

The key to profitability lies in the ability to produce wire harnesses at a competitive and well-understood cost. Photo courtesy ALTEX Inc.

An Increasingly Important Process

“Harness costing is the process of calculating the overall price related to manufacturing the wiring harness,” explains Bartosz Czarnecki, product manager for harness manufacturing and integrated electrical systems at Siemens Digital Industries Software. “It includes not only the price of materials, but also the labor cost and all nonrecurring costs like the engineering effort.

“There could be additional costs, for instance, if there was an issue with the quality of the products,” says Czarnecki. “This we cannot quantify, but we can reduce this risk drastically by using technology such as digital twins.

“Costing is important to harness manufacturers because they are operating on a very low margin,” Czarnecki, points out. “To have beneficial processes, manufacturers must control and maintain their costs very precisely.

“With manufacturing volume changes, increases in labor cost, global problems with supply chains and overall geopolitical situations, the production of harnesses may very rapidly turn out to be unprofitable,” warns Czarnecki. “The goal of proper costing is to gain overall control of the price of harness production, which is critical for low-margin operations and can be challenging.”

According to Czarnecki, both large and small wire harness shops struggle with costing issues. That’s because many factors can interfere with the process, such as fluctuations in production volumes, increasing vehicle configurations and modifications, unstable geopolitical situations that can affect the components’ availability and price, and rules regarding new industry standards and sustainability. All these factors make harness production very complex and dynamic, which makes costing so difficult.

“Costing has always been important,” says Bromm. “The big challenge in today’s world is predictability of changes and market stability. A few years ago, for instance, when there were part shortages, prices were constantly fluctuating.

“Often, after we quoted a price on raw materials, by the time we went to order them the cost had changed,” recalls Bromm. “We were faced with the challenge of either going back to a customer and changing the price or simply absorbing the cost and moving on. That continues to be a challenge today, but it’s more stable than it was during the Covid pandemic.

“There are multiple dynamics around quoting a job,” explains Bromm. “One typical scenario is where we get a drawing from a customer and we quote a price. Then, the company makes changes to its harness design. By the time the customer comes back to us and places the order, several months could have gone by. That forces us to review our quote to make sure that things haven’t changed.

“The amount of time we spend on costing has increased in recent years,” claims Bromm. “That’s mainly because it’s a byproduct of the completeness of the drawings that we receive.

“There’s a lot of research and time devoted to the process,” says Bromm. “For instance, we always consult the IPC/WHMA-A-620 global workmanship standard to make sure that a design doesn’t violate those rules. If it does, that prompts a conversation with the customer.”

Costing Challenges

Unfortunately, everything is not always defined well enough on harness drawings to be able to provide a quote, much less actually build it. That issue can be due to complexity or just a lack of overall awareness and understanding on the part of the person doing the design.

“Sometimes, key areas of a drawing that are critical for us in the build process may be missing,” laments Bromm. “That requires us to go back to the customer and engage in more dialogue.

“The biggest costing mistake that engineers make is not working with complete information,” claims Bromm. “They don’t always account for everything. If you take a drawing at face value, it may not tell you about some issues that can affect labor time. It all starts with documents being final and very clear. Once you have that, costing should be a fairly straightforward process for most companies.

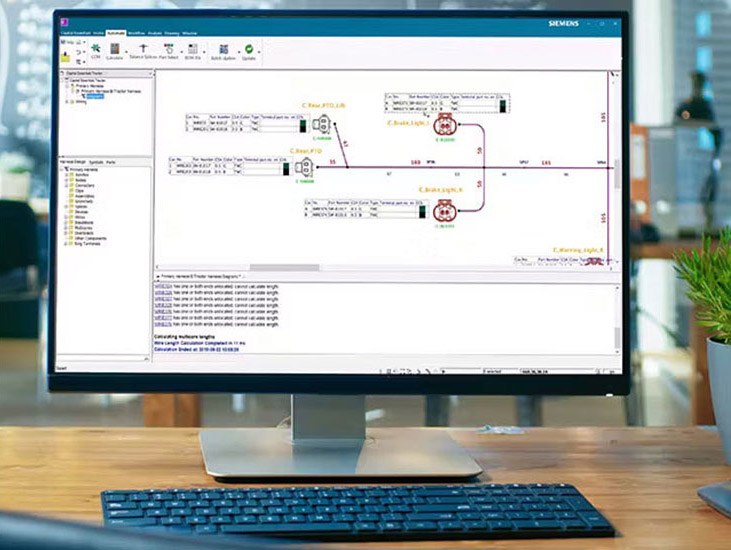

Costing is the process of calculating the overall price related to manufacturing a wiring harness. Photo courtesy Siemens Digital Industries Software

“The fluctuating cost of copper does present certain challenges, depending on the amount of material required,” says Bromm. “Smaller diameter wire with low copper content, for instance, typically has little impact unless we’re using massive amounts. But, larger diameters used for battery cables in electric vehicle applications contain loads of copper. We have to track that to an index to obtain current prices.

“However, you can’t just rely on the copper index alone to be a consistent indicator,” warns Bromm. “Over the last few years, the cost of other areas has been going up in price, such as labor. In most wire harness shops, people still do the bulk of operations. But, people vary in terms of how efficient and fast they are. We typically look for the averages.”

According to Bromm, costing is usually a team process that involves multiple people. “The lead engineer on a project will take a drawing and make sure that the design has compatible parts,” he points out. “Then, we have a materials team and an application tooling team that determine costs. After all their input, everything comes together as a final document.”

No matter the size of the shop, Czarnecki believes that all manufacturers can have different issues with wire harness costing.

“Big operations can have access to global supply chains and more flexible resources, but might require very complex software,” says Czarnecki. “On the other hand, smaller shops might not have the same resources, but their demand for sophisticated software applications could be limited.

Software programs enable fast and accurate wire harness costing and reduce the risk of unforeseen changes. Photo courtesy Siemens Digital Industries Software

“Many circumstances have had direct impacts on the harness costing process in recent years, and the process continues to become more difficult,” claims Czarnecki. “To keep up with the changing industry, companies must go on a digital transformation. In such an environment, it is possible to implement advanced software systems.

“Harness manufacturers today are looking for holistic solutions rather than specific costing tools,” notes Czarnecki. “[These state-of-the-art software tools] allow data to flow quickly and accurately, allow different scenarios to be created to find the best production results, and are flexible enough to adapt to their business processes.

“We are addressing this challenge with Capital software, which is part of the Siemens Xcelerator portfolio,” says Czarnecki. “Capital offers customers a comprehensive, seamless data-driven flow, based on the digital twin approach. This enables fast and accurate costing and reduces the risk of unforeseen changes.

“Capital can mitigate the impact of materials shortages, thus preventing delays,” explains Czarnecki. “[It] ensures the harness design is correct by construction, which reduces the engineering effort and, as a result, accelerates the start of production.”