According to ASSEMBLY’s annual Capital Equipment Spending Survey, sales of fastening tools should increase in 2024. Some 38 percent of assemblers will purchase DC electric nutrunners, pneumatic screwdrivers, cordless rivet setters and other tools this year, about the same percentage as in 2023. Demand will be particularly strong in the medical device, electrical equipment, and electronics industries.

All totaled, assemblers will spend $264.8 million on fastening tools next year, up 13 percent from 2023 sales. Here’s a look at four new fastening tools.

Clutch Tools Are Programmable

AccuTec programmable cordless clutch tools come in pistol-grip and right-angle versions. These lightweight, ergonomic tools are accurate and repeatable with easy-to-set controls. The tools are driven by FEIN’s powerful, brushless PowerDrive motors, which are built in-house.

Two lines are available. Both are suitable for hard and soft joints. Series ASM 18 consists of three pistol-grip models covering a torque range of 0.5 to 12 newton-meters. Speed can be set from 110 to 1,200 rpm. Series ASW 18 consists of six right-angle models covering a torque range of 1.2 to 60 newton-meters. Speed can be set from 20 to 1,100 rpm. Nine angle heads are available to match any application.

FEIN’s parameter control system enables engineers to set the direction of rotation, angle of rotation, and tool speed. The latter can be an exact setting or a percentage of the tool’s maximum speed.

See this company at The ASSEMBLY Show South May 1-2 in Nashville, TN, and The ASSEMBLY Show Oct. 22-24 in Rosemont, IL.

FEIN Power Tools Inc.

fein.com

Photo courtesy of ESTIC America Inc.

Cordless Nutrunners Communicate Via Wi-Fi

ESTIC has added the Master Interface (MIF) Cordless Wi-Fi-based architecture to its cordless torque tool lineup. This technology enables up to 10 cordless nutrunners to be paired with one controller.

The MIF can communicate on both the 2.4 and 5 gigahertz frequencies. The MIF features a dynamic touch screen interface for easy navigation, programming and configuration. The MIF will offer many forms of communication to fit seamlessly into an existing or new line. These include Open Protocol, Toolsnet and Ethernet IP.

ESTIC has also updated the design of its cordless tools. This update raises the upper torque range of its pistol-grip tool to 50 newton-meters, making the tool ideal for interior fastening applications in automobile assembly. The maximum torque output of the company’s right-angle cordless nutrunners is 100 newton-meters.

See this company at The ASSEMBLY Show South May 1-2 in Nashville, TN, and The ASSEMBLY Show Oct. 22-24 in Rosemont, IL.

ESTIC America Inc.

www.estic-global.com

Photo courtesy of WEBER Screwdriving Systems

Controller for Automatic Screwdriving Systems

The C50 controller for automatic screwdriving systems measures the torque, angle and depth of each screwdriving operation. It interfaces with manufacturing execution systems via open interfaces (Profibus, Profinet, Ethernet and Digital). It generates and documents performance results for record-keeping and compliance with each assembly’s process parameters.

The C50 also monitors gradient torque to provide detailed records of the rate of change between torque, angle and depth parameters. By monitoring this information, engineers can consistently achieve the required clamp load at the specified depth.

Some 255 selectable screwdriving programs are available. Custom programs can be created via an open interface. Fastening sequences are visualized on an optional Touch-Panel or a Windows-based computer. Detailed information about screwdriving curves and characteristics can be output. All process signals can be represented on any abscissa. The last 1,000 curves are stored in the controller, and up to 10 curves can be superimposed in visualizations. Options for system diagnosis, log book, backup, and help functions are also available.

See this company at The ASSEMBLY Show South May 1-2 in Nashville, TN.

WEBER Screwdriving Systems

www.weberusa.com

Photo courtesy of DEPRAG Inc.

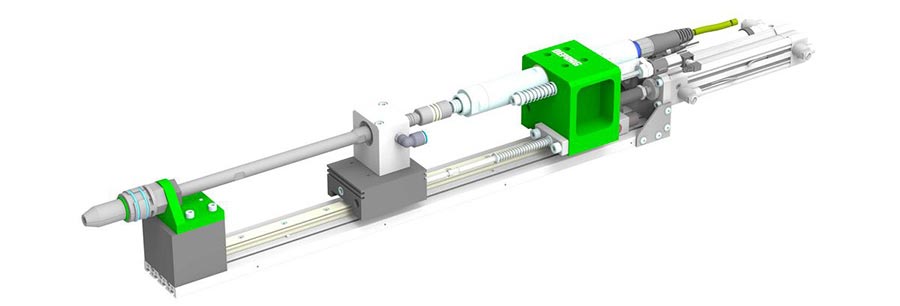

Automatic Screwdriving Module Safe for Battery Assembly

Automatic screwdriving modules are available in various configurations to meet the needs of any application. The modules have a compact, robust design and simple connection ports to facilitate integration into automated assembly systems. Each screwdriving spindle is equipped with a quick-change-chuck that allows bits to be changed quickly.

The newest module has been designed specifically for assembling EV batteries. The module is equipped with special ceramic and synthetic parts to electrically isolate the driver and protect against voltages of up to 1,000 volts. Available in single or multispindle versions, the module has special gripper jaws to avoid dropping the screw onto the workpiece and causing a short-circuit. A gentle screwfeeder and a vacuum port at the drive head keep particulates out of the assembly. The module meets ISO 6469-3 and DIN EN IEC 60900 requirements for electrical safety.

See this company at The ASSEMBLY Show South May 1-2 in Nashville, TN, and The ASSEMBLY Show Oct. 22-24 in Rosemont, IL.

DEPRAG Inc.

www.depragusa.com