Assembly Presses

Servo-driven presses may have gained market share in recent years, but there’s still plenty of work for pneumatic and hydropneumatic presses on assembly lines.

Read More

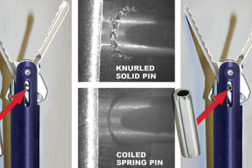

Walking Beam System Assembles Medical Device

Centrifugal feeders singulate and orient cylindrical parts.

May 1, 2013

Get our new eMagazine delivered to your inbox every month.

Stay in the know on the latest assembly trends.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing