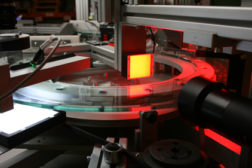

Test and Inspection Assembly

Hoffmann on Testing

Vote for Faster Test System Builds

These tips can help you avoid delays in implementing leak testing and functional testing systems.

October 25, 2012

Get our new eMagazine delivered to your inbox every month.

Stay in the know on the latest assembly trends.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing