Home » Keywords: » spin welding

Items Tagged with 'spin welding'

ARTICLES

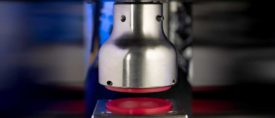

Spin Welding for Plastics Assembly

Enhanced data gathering and automation features complement spin welding’s ability to join plastic parts with a round-to-round interface.

February 1, 2022

Comparing Methods for Plastics Assembly

Engineers have myriad options for joining plastic parts. Which is best for your application?

August 5, 2014

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing