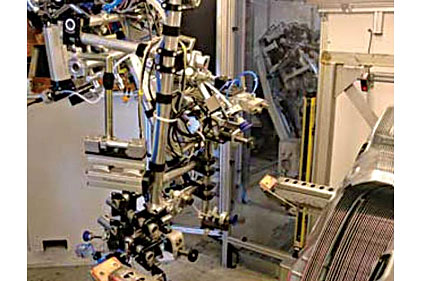

The station features three KUKA robots: one for spot welding and two for handling the parts. The parts-handling robots are equipped with grippers and integrated vision systems. KWD uses Cognex VisionPro 3D image processing software in conjunction with the vision systems.

As welding begins, one robot is positioned in front of the component magazine. Inside the magazine, arranged horizontally in a stack, are small parts to be welded to the side panel. The robot verifies the correct position of the parts and grabs them, whereupon pins secure a side panel in place.

Meanwhile, a second robot with a two-sided gripping system positions itself in front of the transport rack that contains large parts arranged in a vertical stack. This robot checks the position of the transport lock, measures the position of the large parts, and picks them up. Subsequently, both robots move to the loading station and put down the parts in the correct position and in the logical sequence.

Welding is then performed by a spot welding robot. Afterward, vision systems in the first and second robots check the number and location of the welds, and whether they were placed in the predefined fields. The vision systems also examine whether the roots of the weld points are correct based on the parameters of the welding control.

Data obtained from the testing is archived, and images are assigned to the associated parameters. In this way, KWD achieves complete traceability and documents and verifies quality.

Each welded component is then removed by the second robot and placed in the transport rack for finished parts. Once the required number of finished parts is stacked in the rack, a signal is sent to transport logistics, which collects the full rack and delivers a new empty rack. The process is then repeated.

For more information on 3D vision software, call 508-650-3000 or visit www.cognex.com.