In applications relating to refrigeration, air conditioning and ventilation technology, users frequently notice that the selected fan installed in the device does not run as quietly as expected. Such fans often generate a level of operating noise considerably higher than that stated in the product documentation, simply because the values stated in the documentation reflect measurements made under optimal test conditions. In the applications themselves, however, the fans are subject to inflow disruptions of varying intensity that result from real life installation conditions. These disruptions generate a non-uniform inflow field causing additional noise which, as perceived by the human ear, often has an annoying or even uncomfortable low frequency tonal quality. Specially designed air inlet grills can reduce these disturbances by essentially straightening the inflow and significantly lowering the level of noise generation.

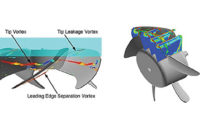

Fans in air handlers, heat pumps, air conditioners, refrigeration units, electronics cabinets and filtration equipment are installed in many different ways, with varying dimensions and designs. Differences occur in the positioning of the openings required for ventilation, in the heat exchanger surface and in the packing density. When adjacent fans or the walls of a device near the fan inlet create obstacles or asymmetrical constrictions to the air flow, powerful vortices can form that generate high levels of turbulence (Figure 1). This turbulence then hits the rotating blades of the fan, causing major fluctuations in the pressure and speed at the front edge of the blade. This can result in a noticeable increase in broadband air flow noise, but even more significant are large increases in the low-frequency narrowband, tonal frequency noise components.

The tonal components consist of the blade-passing frequency and its harmonics. The blade-passing frequency is a function of the fan speed and the number of blades. An axial fan with five blades spinning at 1,200 rpm, for example, would result in a blade-passing frequency of 100 Hz. These types of low frequency tones are perceived as an audible hum that is particularly difficult to attenuate. It is not possible to compensate for disruptions to the inflow by optimizing the fan. Providing mechanical isolation or insulation can involve prolonged analysis or experimentation that still may not yield satisfactory results.

One solution to reduce the noise-generating disruptions to the inflow is to deploy an air straightening grill on the fan intake. Such grills, properly designed, can be equally effective with both axial and centrifugal fans. Their use does not impact fan efficiency. Examples of air inlet grills for both fan types are shown in Figure 2. These are easily mounted to common fan housing styles and also lend themselves to field retrofits in many situations. Actual results of sound pressure level measurements performed on an example condenser are shown by the sound spectrum in Figure 3. The use of the inlet grill reduced the sound pressure level and considerably weakened the tonal noise. Typical results on many application types including central air handling units, air purifiers, air-water heat pumps and condensers show that a reduction in the overall sound power level of 3 dB(A) and a sound pressure level reduction of 9dB or more in the blade-passing frequency are possible.

Applications in the field of ventilation, refrigeration and air conditioning technology have an additional option regarding noise reduction with the help of another passive component. This time the component works on the exhaust side of the fan and is restricted to use on axial fans. Adding a diffuser to the exhaust side of axial fans is a common technique used in agriculture and is often seen on animal barns where they are typically referred to as discharge cones (Figure 4). These are often of thin sheet metal construction which is sometimes even delivered as flat stock to be mounted into a cone shape in the field. But until recently, nothing similar has been available that was easily adaptable to more commercial type applications.

These applications often use unducted axial fans and such an unducted or free exhaust can be an underestimated source of energy loss. This is because the total work generated by a fan is the sum of the static pressure and velocity pressure. Axial fans impart a relatively high velocity to the air flow, meaning low static pressure and high velocity pressure at the fan discharge. Freely exhausting the airflow at the discharge, as in unducted fan applications, loses the energy of the velocity pressure as turbulence and eventually as heat to the environment. Since these applications typically have ample clearance above and between fans, a well-designed diffuser can be added to the fan exhaust to recover a significant portion of this velocity pressure as static pressure and use it to overcome the resistance to air flow in the application.

The diffuser shape provides a gently expanding diameter to gradually reduce the velocity of the air flow, resulting in a reasonably efficient conversion of velocity pressure to static pressure. Static regain is the term often used for this. Since the diffuser recovers some of the velocity pressure as static pressure before the air flow escapes to the atmosphere, the work required of the fan to overcome the system resistance is reduced. Consequently, the fan speed can be lowered—reducing both noise and input power—while still maintaining the same air flow.

Examples of axial fan diffusers mounted in common applications are shown in Figure 5. As with the air straightening grill on the fan inlet, the diffuser hardware is made from light, reinforced composite material and is easily mounted to the exhaust side of a typical axial fan housing by the fan OEM or as a field retrofit with a bit more work. The ability to lower the fan speed as a result of the efficiency gained from the diffuser while maintaining the same air flow can result in an overall noise level reduction of 5dBA or more, mainly from the mid-frequency sound spectrum. In axial fan applications where the air inlet grill and the diffuser can be used together, the synthesis of their effect on the fan intake and exhaust air streams can create an even more substantial impact on a combination of low frequency tonal noise and mid-frequency broadband noise.