In 2016, materials scientist Cora Leibig, Ph.D., recognized an opportunity in the 3D printing industry to make more robust parts from materials engineers know and trust. She understood the promise of 3D printing, its potential to transform supply chains, and the industrial design possibilities—if only the right materials could be printed, like thermoset elastomers.

Drawing on more than 20 years of industry experience, Leibig founded Chromatic 3D Materials in Golden Valley, MN, and invented reactive extrusion additive manufacturing. Today, the business serves more than 50 customers and development partners across a range of industries in the U.S. and abroad.

Chromatic’s process can be used to make solid seals and gaskets with smooth surfaces in sizes from 10 millimeters up to 1 meter. Photo courtesy Chromatic 3D Materials

Chromatic’s process can be used to make industrial components, such as bellows and bladders. Photo courtesy Chromatic 3D Materials

The company’s RX-AM materials and technology platform enable companies to print industrial-strength elastomeric parts anytime, anywhere—from one part to 1 million. The RX-AM additive manufacturing process relies on chemical reactions. The materials do not require melting, lasers or post-processing. The process can be used to make solid seals and gaskets with smooth surfaces in sizes from 10 millimeters up to 1 meter. It can be used to make industrial components, such as belts, bellows, bladders, grommets and rollers. And, it can be used to make supports, pads, structures, hooks and other functional attachments for textiles and apparel. Such components can be printed directly on fabric. No adhesives, fastening or stitching is needed.

One niche that’s successfully being served by Chromatic is the manufacturing of spare parts that have little demand on the market, yet are crucial for the operation of machines or plants. Chromatic enables companies to have such parts printed quickly on demand. A recent example was a polyurethane buffer for a bogie that was originally made in 1967. With no material data and only an old 2D drawing, it would have been far too expensive to attempt to reproduce such a part. Taking an equivalent component as a basis, Chromatic created a 3D model of the part, printed it, and tested it. The customer was able to obtain a replacement part quickly and at low cost.

“We created both the RX-AM material and the technology platform for the additive manufacturing,” says Bart Engendahl, the managing director of Chromatic 3D Materials GmbH, the company’s subsidiary in Selfkant, Germany. “The resins that are used on the platform are developed in-house. The resin development is something that distinguishes Chromatic 3D from the competition. Our seals are in demand for applications such as machines, trains, cars and even airplane interiors.”

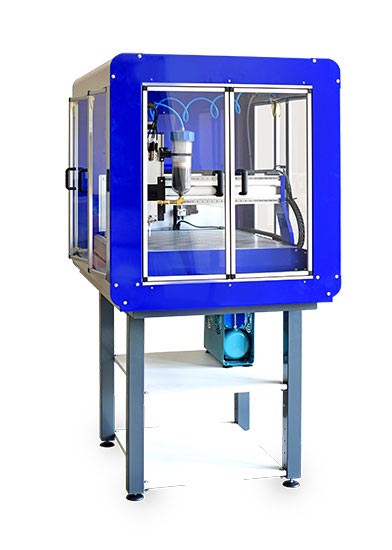

The RX-AM additive manufacturing process relies on chemical reactions. The materials do not require melting, lasers or post-processing. Photo courtesy Chromatic 3D Materials

Dispensing Technology Is Key

For Chromatic’s process to work, however, the company needed accurate and reliable technology to meter, mix and dispense two-component polyurethanes. The technology would also have to be compatible with 3D printing control software. Chromatic had tested piston-driven and pneumatic dispensing systems, but it wasn’t happy with the results. Those technologies could not provide the accuracy and consistent flow rate that the company was looking for.

The Vipro-Head 5/5 printhead from ViscoTec solved the problem. Based on the “endless piston” principle, the device can achieve a theoretical volume flow between 0.03 and 6 milliliters per minute per printhead half. It can print dots or beads, and it can accommodate mix ratios ranging from 1-to-1 to 5-to-1. The printhead can dispense a variety of materials, such as silicones, polyurethanes, epoxies, acrylates and polyester resins.

The two components are dispensed separately into a static mixer. A programmable “suck-back” feature ensures a clean shut-off of dispensing and prevents dripping of excess material. A sensor monitors fluid pressure and will shut down the system if pressure exceeds a set limit. The system automatically levels fluctuating process parameters. If, for example, material viscosity changes due to temperature fluctuations, the system will automatically compensate.

ViscoTec engineers helped Chromatic integrate the Vipro-Head 5/5 into the company’s 3D printer.

With RX-AM technology, companies can print industrial-strength elastomeric parts anytime, anywhere—from one part to 1 million. Photo courtesy Chromatic 3D Materials

“The quality of the end product from Chromatic 3D is wholly dependent on a reliable and precise fluid handling process,” says Simon Kasböck, business development manager for additive manufacturing at ViscoTec. “Only with this in place can we provide precise components in the material quality specified by the customer.”

“Working together, we established the perfect printing process for a very complex material,” says Kasböck. “Over the course of our collaboration, we even developed a four-component variant. This went incredibly well, since Chromatic 3D developed the corresponding materials and fully configured these for the process in question. Taking the whole package into consideration, we all see great potential for the Chromatic 3D manufacturing process: The excellent material properties and the stable process make it easy to scale up.”

Moving forward, ViscoTec will continue to support Chromatic in optimizing the dosing process. “Naturally, we will also remain on board for special tasks in future, such as the development of new variants of our print heads,” says Kasböck. “Additive manufacturing with fluids and pastes is not as well-known as filament 3D printing or selective laser sintering. But, companies such as Chromatic 3D are demonstrating the potential of the technology.”

ASSEMBLY ONLINE

For more information on dispensing technology, read these articles:

Potting Head Provides More-Precise Dispensing

Micro Dispensing is Key to Major Product Improvements

Dispensing Filled Materials