In the world of manufacturing, precision and accuracy are paramount. Metal components, integral to countless products, must maintain their intended straightness and flatness. However, they often face challenges like bending, warping, or skewing due to factors such as heat treatment and improper storage. In such situations, manufacturers need a reliable solution to restore these components to their desired specifications. Traditional methods, relying on skilled operators wielding hammers and tongs, can be subjective and time-consuming. This guide introduces you to the innovative Promess Straightening Work Station, which combines cutting-edge technology and efficiency to straighten and flatten metal components while reducing cycle times to just 1-2 minutes.

In manufacturing, precision is the bedrock of quality and functionality. Metal components, which should be perfectly straight and flat, often lose their intended shape due to various factors like heat treatment and improper storage. When the performance and fit of your products rely on these components, it becomes crucial to have a dependable solution. Enter Promess and our Straightening Work Station, a game-changer in the pursuit of precision.

Traditional techniques for straightening and flattening components usually involve skilled operators using hammers, tongs, measuring devices, and fixtures. While these professionals do their best to restore components, the process is often subjective, relying on the operator's judgment, sometimes referred to as "eyeballing it." Additionally, there are times when the go-to operator is unavailable, leading to delays in production. It's evident that a more reliable and efficient method is needed.

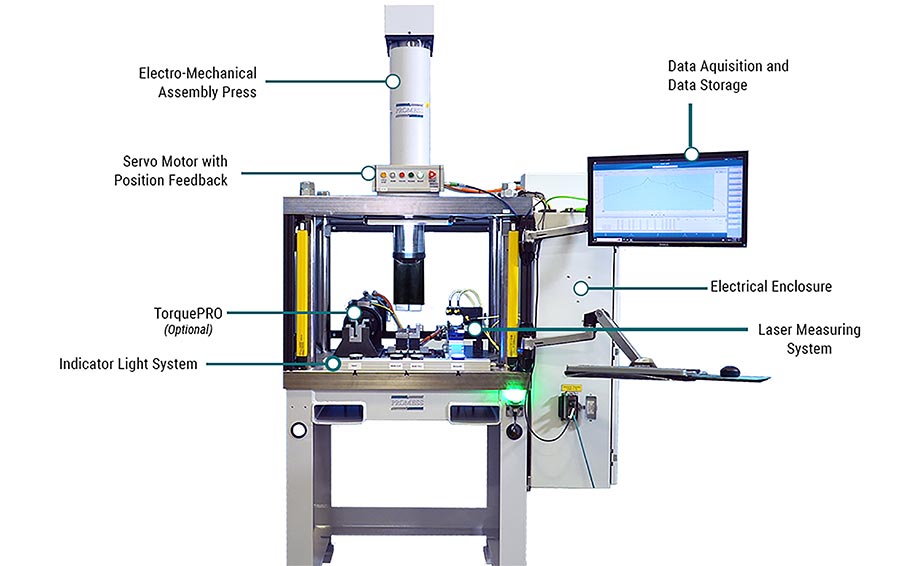

Promess' Straightening Work Station is a comprehensive system designed to revolutionize the straightening and flattening of metal components. It integrates advanced technology, including UltraPRO software and controls, an Electro-Mechanical Assembly Press (EMAP), TorquePRO, specialized fixtures, and a laser-measuring station. This powerful combination allows for precise assessment of a component's flatness and straightness along both short and long axes.

The Promess Straightening Work Station operates through a straightforward yet highly effective process:

- Measurement: The process commences with laser-based measurement to establish a baseline for the component.

- Fixture Selection: Indicator lights guide the operator, indicating the appropriate fixture for the component based on its shape and size.

- Confirmation: Built-in sensors and indicator lights confirm the correct placement of the component.

- Two-Handed Activation: For safety, the operator uses two-handed anti-tiedown cycle-start buttons to initiate the process.

- Precision Adjustment: The EMAP and TorquePRO units apply calculated force and torque based on the initial measurements.

- Iterative Process: The system allows for multiple iterations, re-measuring and adjusting as needed until the component meets the desired specifications.

The Promess Straightening Work Station offers a range of advantages, including:

- Precise control over the straightening process.

- Monitoring of force and torque.

- Generation and storage of graphical representations for every part.

- Drastic reduction in cycle time, from 15 minutes to just 2 minutes.

- Elimination of manual hammer and tong processes.

- A solution to address labor shortages, ensuring consistent quality.

The Promess Straightening Work Station includes key components such as:

- EMAP 120kN for controlled force application.

- TorquePRO 500Nm for precise torque application.

- Laser measuring system for accurate assessment.

- Data acquisition and storage for quality control.

In an industry where precision and quality are non-negotiable, the Promess Straightening Work Station sets a new standard for consistency and efficiency. This advanced solution not only streamlines the straightening process but also provides real-time feedback and control. By adopting this technology, manufacturers can be confident that their components consistently meet the required straightness and flatness standards, ensuring that "bad" components never find their way into the end-users' products. Embrace the Promess Straightening Work Station to enhance your manufacturing process and deliver the quality your customers deserve.

Promess Inc.

Promess Inc.

Promessinc.com

promess@promessinc.com

810-229-9334