Adhesives offer many benefits over mechanical and thermal methods of assembly.

Adhesives distribute load evenly over a broad area, reducing stress on a joint. Adhesives are applied inside the joint and are nearly invisible within the assembly. They resist flex and vibrational stresses, and will form a seal as well as a bond to protect joints from corrosion. They join irregularly shaped surfaces more easily than fastening or welding. They add minimal weight to an assembly, create virtually no change in part dimensions or geometry, and can join dissimilar substrates and heat-sensitive materials.

Whether you need a UV-cure adhesive to assemble a medical device or a two-part epoxy to encapsulate electronics, you’ll find it at The ASSEMBLY Show South. Here’s a look at some of what you’ll see.

Click on the headings below for product information.

The UP4000 series is a comprehensive family of two-component methacrylate adhesives with a full range of performance properties, work times, and cure times to meet specific application requirements. They provide strong bonds to similar and dissimilar materials. They have excellent aging, weathering and environmental resistance properties, making them a good choice for marine, automotive, aerospace, and sign and display applications. The adhesives create tough, durable bonds, with excellent impact and shock resistance.

Dynamic Adhesives Solutions

https://dynamicadhesivesolutions.com

Fusionbond 370 is a two-component methacrylate adhesive specially formulated for structural bonding of thermoplastics, metal, wood and composite assemblies. It is an excellent choice for composite bonding applications in the marine, automotive and construction industries, because it requires virtually no surface preparation. It provides superior toughness at temperatures from -67 to 250 F. Supplied in a dual-cartridge syringe, the adhesive has a 1-to-1 mix ratio. It is resistant to fatigue, impacts and salt spray, and it has good gap-filling ability.

Hernon Manufacturing Inc.

www.hernon.com

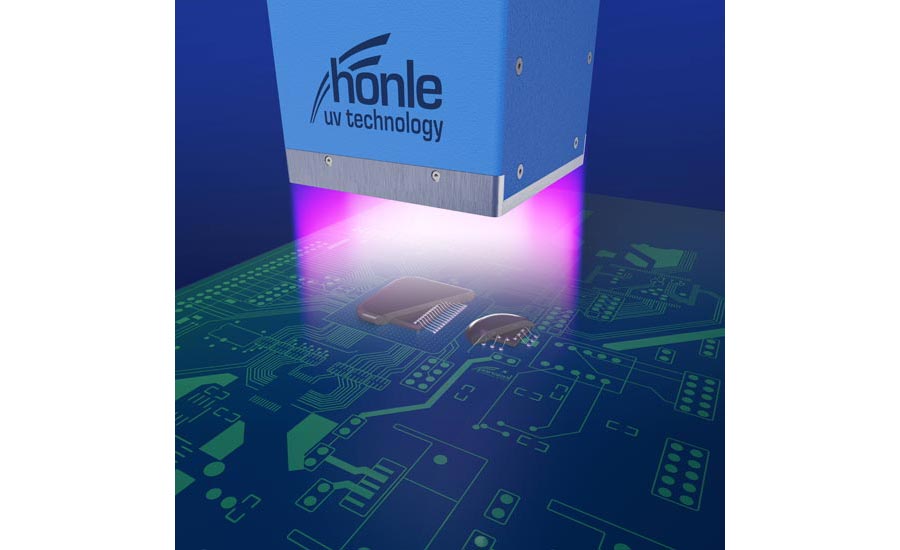

Vitralit BL UC 1101, 1102 and 1103 are UV-curing, black epoxy resin adhesives. The adhesives can be cured in layers 1 millimeter thick or more using only UV light, eliminating the need for a secondary curing mechanism. Unlike conventional single-component epoxies, which must be kept cold or frozen, Vitralit adhesives are shipped and stored at room temperature.

The adhesives are suitable for component encapsulation, glob top, or edge bonding in electronics production. They can also be used as optical adhesives in applications requiring high optical density values.

Vitralit BL UC 1101 is perfect if a thick layer of adhesive is needed. It cures reliably in thick layers up to 1.3 millimeter, resulting in an optical density of up to 3.9. If a high optical density in lower layer thickness is needed, Vitralit BL UC 1103, with OD values of up to 6, is the best option. In optoelectronic component assembly, Vitralit BL UC adhesives minimize reflections and can safeguard the sensitive transmission values required for automotive sensors. All three adhesives have high glass transition temperatures, low shrinkage, and low coefficient of thermal expansion.

Panacol USA Inc.

www.panacol-usa.com

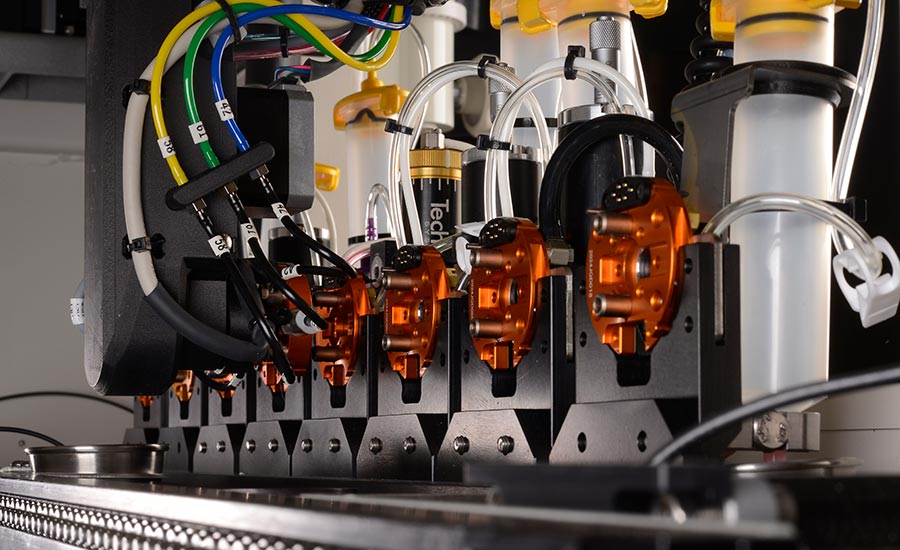

The PrecisionCoat VI selective conformal coating and dispensing system is fully programmable. Available in multiple configurations, this flexible system can apply acrylics, silicones, epoxies, urethanes, latex and other materials onto complex assemblies. The Automatic Quick Change (AQC) feature allows the use of eight separate tools within a single machine. Manufacturers can individually position valves or heads with different materials and functions. This allows manufacturers to automate application of multiple materials within a single coating profile. Numerous head options are available, including spray valves, dispense valves, UV spot curing lamps, jetting valves and micro spray valves.

Specialty Coating Systems

https://scscoatings.com

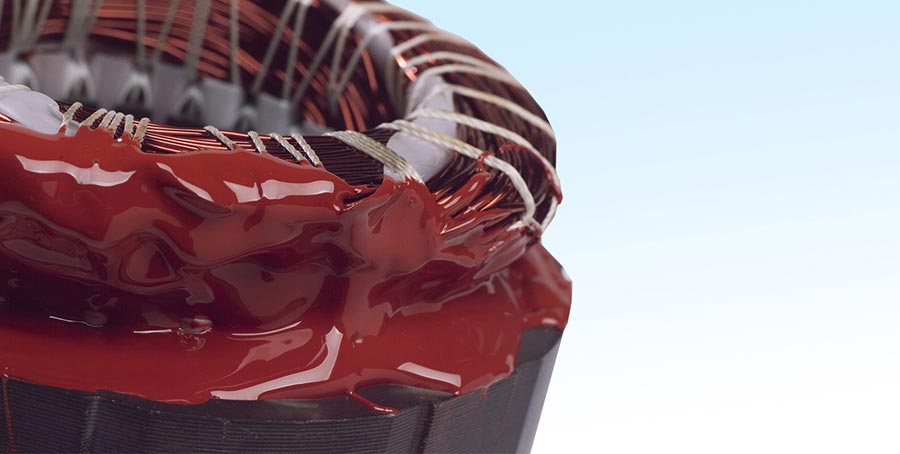

AA-210-3 two-component epoxy system has passed extensive smoke and toxicity testing. By passing ASTM E-662-15a smoke density tests and Boeing specification support standard BSS 7239 Rev: A1-18-88, the epoxy is a good choice for bonding, sealing, coating and potting in the light rail industry. This insulating epoxy is designed to encapsulate sensitive electronic components and transformers. It has excellent noise reduction and vibration characteristics. The epoxy is flexible after curing, yet still exhibits excellent electric properties and low weight loss at operating temperatures exceeding 180 C. Heat will accelerate the curing process and provide the best physical properties.

Star Technology Inc.

https://star-technology.com

Thermally conductive adhesives are formulated to efficiently transfer heat in applications such as electric motors, electronics and LED assemblies. Typically silicone-based, they are known for their excellent thermal stability and electrical insulation properties. Dissipating heat helps maintain lower operating temperatures, extending the components' lifespan and ensuring consistent performance.

ThreeBond International Inc.

https://threebond.com

Epoxies are critical for achieving the performance characteristics of drones, such as durability, lightness, and resistance to environmental conditions. Key uses include structural components, composite materials, electronic encapsulation, and thermal management.

Metal Paste with 215 Hardener is a thixotropic structural adhesive that cures at room temperature and possesses superior strength at temperatures of 350 F.

High-Temp Adhesive with 210 Hardener is a two-component, low-viscosity epoxy with excellent strength at 300 F. It cures at room temperature.

Uni-Bond 1070 with 601 Hardener is a general-purpose laminating adhesive with a low viscosity.

Flex A Bond with 740 Hardener is available in standard, sprayable and paste formulations. A key advantage of this structural adhesive is its ability to join hard-to-bond materials, such as PTFE, nylon, ceramics and stainless steel.

Hi-Strength Tuff Bond with 250 Hardener is a non-sagging, thixotropic, high-strength adhesive for a various substrates, including hard-to-bond materials such as PTFE, nylon, acetal and stainless steel. It cures at room temperature.

United Resin