Home » Keywords: » epoxy adhesives

Items Tagged with 'epoxy adhesives'

ARTICLES

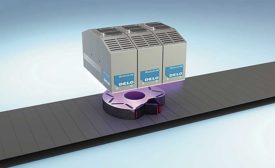

Automated Dispensing for EV Motor Assembly

A fully automated line dispenses and cures a filled, two-part epoxy to encapsulate bus bars for ev motors.

June 8, 2023

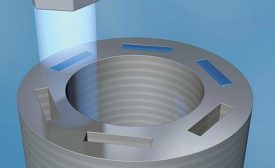

Assembling EV Motors With Adhesive

Magnets, rotors, shafts, stators and other metal components require epoxy.

May 17, 2022

Carbonic Cleaning for Adhesive Bonding

Carbonic cleaning safely and consistently removes contaminants from materials to prepare them for adhesive bonding

May 1, 2020

Bubble-Free Potting of Capacitors

Scheugenpflug’s vacuum potting system ensures quality encapsulation of high-voltage capacitors for medical devices.

May 1, 2018

Alternative UV-Curing Adhesives

A new generation of UV-curing silicones and epoxies are increasingly being used in automotive and electronics applications.

March 6, 2018

Adhesives Aid Truck and Trailer Assembly

High-strength adhesives and sealants can improve the durability and appearance of trailers and truck bodies, while enhancing throughput.

June 7, 2017

Heat-Resistant Adhesives

Epoxies top the list of adhesive chemistries that can take the heat.

May 5, 2017

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing