Home » Keywords: » bar code reader

Items Tagged with 'bar code reader'

ARTICLES

What’s New With Auto ID

New technologies are helping assemblers keep track of product on the line.

August 4, 2022

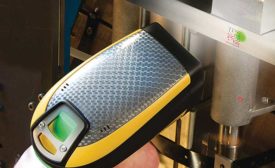

Reading Codes on the Assembly Line

Many assembly operations begin with the scanning of a 1D or 2D bar code.

August 4, 2020

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing