Home » Keywords: » wire marking

Items Tagged with 'wire marking'

ARTICLES

These success stories highlight the need to use the latest wire processing technology on the shop floor

Read More

Ink-Jets for Marking Wire

Ink-jet printers are a fast, flexible technology for marking wire

January 16, 2019

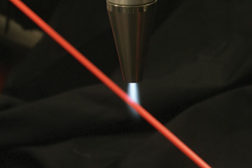

Improving Printability of Wire and Cable

By raising surface polarity, atmospheric plasma treatments optimize the adhesion properties of insulation materials.

April 1, 2013

Get our new eMagazine delivered to your inbox every month.

Stay in the know on the latest assembly trends.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing