Home » Keywords: » robotic screwdriving

Items Tagged with 'robotic screwdriving'

ARTICLES

Cobots optimize assembly and packaging by 30 percent.

Read More

Advances In Fastening Tools

New fastening technology promises to improve ergonomics, boost output, reduce costs and increase quality.

March 2, 2023

Screwdriving With Cobots

Labor shortages have forced manufacturers to adopt collaborative technology

February 1, 2023

Screwdriving Gripper Mimics Two-Handed Assembly

Researchers have developed a single end-of-arm tool that can simultaneously hold a part in place and install it at the same time.

November 29, 2022

Beyond the Welding Line: Robots and Automotive Assembly

Humans and machines are collaborating on trim lines.

April 12, 2022

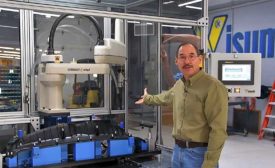

New Tech for Robotic Fastening

Screwdriving is a perfect application for Cartesian, SCARA and six-axis robots.

February 8, 2022

2020 Assembly Plant of the Year: There’s No Looking Back at Murakami

The Campbellsville, KY, plant excels at continuous improvement and workforce development

October 6, 2020

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing