Today’s automobiles contain dozens of electric motors. They adjust the mirrors, position the seats, aim the headlights, provide heating and cooling, and raise and lower the windows. In fact, a luxury car might have as many as 120 electric motors of various sizes.

Swiss manufacturer Sonceboz SA produces more than 70,000 stepper motors a day for the automotive industry. The motors are produced on a high-speed, multistation automated assembly line at the company’s headquarters in Sonceboz, Switzerland. Designed and built by Mikron Automation, the line assembles the motors at a rate of one per second.

“Four years ago, we had to improve the capacity and efficiency of our stepper motor production activities,” says Michael Geiser, production engineering manager for Sonceboz’s Instrumentation business unit. “Mikron offered us the best solution.”

Mikron and Sonceboz worked closely together to design the assembly line. “Sonceboz gave us clear requirements, such as specific cycle times,” says Lionel Rochat, project manager at Mikron. “To meet their needs, we had to find some innovative solutions. We couldn’t simply use an existing system from another project.”

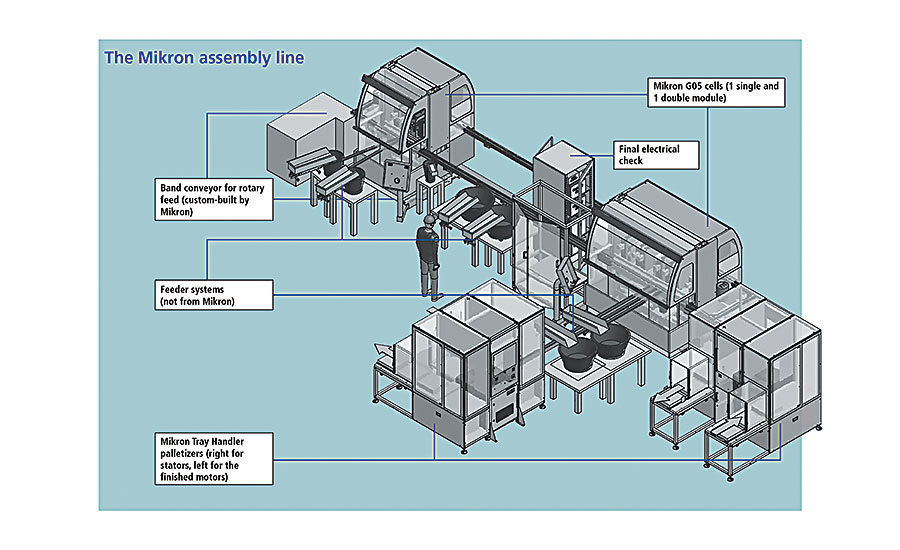

After a year of intensive cooperation, the Mikron line was put into operation. It comprises two Mikron G05 cells (a single module and a double module), two Mikron tray handlers, and two feeder systems produced by another vendor.

Preassembled components (a stator with two coils) are loaded onto the assembly line from the tray handler. A custom-built conveyor transports them to the first G05 cell, where additional components are installed, including a toothed drive gear. These components are transported to the line via feeder systems.

Before the finished motors leave the assembly line via a second tray handler, a final electrical test is carried out.

“To utilize the full potential of the Mikron system, we invested a great deal of time in training our employees,” adds Geiser.

The G05 is a modular, preconfigured automated assembly chassis. The machine uses a cam drive for all primary motions, guaranteeing synchronization between the working units and the pallet-indexing system. Fixtured pallets enter the cell and are advanced in steps of 60, 120, 160, or 240 millimeters, depending on the model. Indexing repeatability is ±0.01 millimeter. Each assembly step is followed by a systematic check to ensure continuous and consistent quality.

With 60-millimeter pallets, the cell can accommodate up to 16 processing units.

Multiple cells can be linked together, depending on project requirements, allowing full layout flexibility. The machine’s linear design ensures accessibility for both operational and maintenance personnel. The machine can accommodate speeds up to 100 cycles per minute.

The system can be linked to manual and semiautomatic workcells, giving assemblers the option for progressive investment to a fully automated line.

Three control systems are available: B&R industrial PC, Siemens PLC or Allen-Bradley PLC.

Mikron’s tray handlers are ideal for parts—like small motor stators—that could be damaged or contaminated if fed from vibratory bowls. The device can handle a single stack or multiple stacks of trays ranging in size from 200 by 300 millimeters to 400 by 600 millimeters. Tray exchange time is 2.5 seconds for a 600-millimeter tray.

Capable of operating in a class 10,000 clean room, the tray handler is equipped with a three-axis gantry system for picking and placing parts. Optional capabilities include tray rotation, lid handling, inkjet printing, and vision inspection.

Since the assembly line was commissioned, the two companies continued to cooperate. “We rely on Mikron’s excellent service,” says Geiser. “Problems need to be resolved as quickly as possible, as idle times are extremely expensive.”

For more information, call Mikron at 303-364-5222 or visit www.mikron.com/automation.

Editor’s note: Whether you’re a systems integrator or the in-house automation team of an OEM, if you’ve designed a system that you’re particularly proud of, tell us about it. Send an e-mail to John Sprovieri, editor of ASSEMBLY, at sprovierij@bnpmedia.com, or call 630-776-0924.