Whether it is text, numbers, bar codes or even just a pattern to aid identification, producing clear, accurate and long-lasting marks on wire and cable is becoming increasingly important. Such marks can reduce harness assembly errors, simplify harness repair, and deter the use of substandard or counterfeit wire and cable.

Fortunately, harness assemblers have many options for marking wire and cable. There is no single best marking method, purely because no two applications are the same. A range of factors must be considered when deciding on the right coder for your assembly operation.

The first thing to consider is what information you need to put on the wire and cable. Often, codes are simple. Due to space constraints, markings mostly consist of one line of alphanumeric text. However, pitfalls can arise for manufacturers that must code varying message content on a range of different products or for specific customers. On top of that, industry standards can always change. If new regulations mean additional coding must be applied to your cables, could your current marking machine handle it, or would it be rendered obsolete?

The next thing to consider is what substrates you will be marking on. If your assembly line makes a range of products, can your coding equipment acceptably mark each substrate at the same standards of legibility and longevity? The color of your wire and cable matters, too. Can your marking equipment print high-contrast coding on colored cable? Similarly, some gadget manufacturers are now using wire and cable with polyethylene insulation to eliminate halogen from their products. Can your marking equipment accommodate such changes?

Another thing to think about is your production environment, which can have a big effect on the reliability of your coding equipment. Hot and dusty or dry and greasy environments mean your coder will need shielding to produce reliable markings. Make sure the device’s IP rating matches your requirements. Printers with IP55- or IP65-rated steel enclosures offer protection against liquid and particle contamination.

Finally, consider your budget. This doesn’t just mean the initial cost of the coder itself; it’s the total cost of ownership. By compromising on the initial purchase price, could you end up paying more over the long run with unexpected breakdowns or less reliable coding? Similarly, leasing a coder may make better financial sense than buying, particularly if your company tends to experience peaks and troughs in production.

Keeping Costs Down

Controlling costs is important for any assembly operation. For wire marking, the first way to do this is to minimize coding errors. A common cause of coding errors is to use marking equipment with a complex user interface. When an interface is not intuitive, it’s easy for operators to inadvertently choose the wrong message to be coded. Operators may even need special training because the system is so complex.

Modern marking equipment often features large touch screen displays that are no harder to operate than an iPad. Newer coders allow print information to be saved in the system so an operator can choose information from a list and preview the message before it’s printed. This is much faster and less error-prone than manually entering the information each time. Some marking equipment can connect to a central computer or smartphone app, so messaging can be changed on the fly without having to be present on the factory floor.

Choose the Right Technology

It’s important to match the coding technology to the application. The wrong technology could print information that becomes illegible over time or that may not even adhere to the substrate at all.

There are two main types of marking technology: continuous ink-jet and laser.

Both technologies are flexible. Because they are noncontact technologies, users can change messages quickly at the press of a button. They can also print alphanumeric text in a range of sizes and styles. Codes can be changed without stopping the printer, which saves downtime.

Ink-jet printing is a popular choice. Continuous ink-jet systems work by expelling electrically charged ink droplets from a printhead and passing them through an electric field.

The droplets are created inside the printhead by the pulsing of a piezoelectric crystal. The droplets are charged by an electrode as they break off from the ink-jet. (The printer recirculates any ink droplets that don’t get charged.) The charged droplets then pass through an electrostatic field between deflector plates. The combination of the speed and charge determine the position of the droplet on the substrate. Up to 120,000 of these tiny droplets—half the diameter of a human hair—are expelled every second.

Although continuous ink-jet systems are cost-effective, it’s important to be aware that the use of consumables means there will be an ongoing cost for operating this equipment.

Ink-jet printing is fast and versatile. It can print on most plastics, and it can print multiple lines of text and simple graphics at up to 2,600 characters per second.

A wide range of inks is available to use with ink-jet printers. Pigmented inks of different colors offer superlative contrast and durability to ensure codes stand out on any color substrate. Additionally, UV-cure inks provide excellent adhesion, light-fastness, and resistance to a range of chemicals—perfect for preventing code transference during production and fading during end-use.

A model with a compact printhead can print marks on virtually any side of the product in any orientation. In addition, lighter models of ink-jet printers have been introduced in the past few years. These machines are easy to move across different production lines. Setup is quick and easy, which is great for smaller producers that operate multiple lines at different times of day.

Laser markers are often seen as a more expensive alternative to ink-jet printing. However, this isn’t strictly true. Yes, the initial outlay for a laser marker can be higher. But, the trade-off is that there are no consumables, so significant savings can be had over the life of the unit. This is ideal for high-volume production environments where the coder is likely to run continuously with minimal downtime.

Another key benefit of laser technology is that it creates permanent marks. The markings are literally etched into the surface of the product. This is ideal for cable and fiber-optic components that are expected to be used for many years and that require traceability no matter how old or warn the component is.

Since there is no ink involved in the laser coding process—and therefore no drying time—the risk of smudging is eliminated, so lasers are ideal for operations involving high-speed cable winding.

Lasers produce very high quality markings, too. Logos and graphics, such as international standards symbols, can be coded onto the product alongside bar codes, Data Matrix codes and alphanumeric text. Readability is particularly good when marking PVC insulation, due to a chemical reaction that causes a color change in the material itself. (Because hydrogen chloride is produced when lasers mark PVC, fume extraction is necessary.)

For more information on ink-jet and laser marking equipment for wire and cable, visit www.linxglobal.com or email sales@linxglobal.com.

Ink-Jet Printers Reduce Downtime Down Under

Australian manufacturer Bambach produces wire and cable for a variety of industries, including automotive, heavy equipment, marine, defense, railroad, communication, solar power, and sound and lighting. Established in 1936, the ISO 9001:2008 certified company is headquartered in Brookvale (a suburb of Sydney) and maintains satellite operations in Coopers Plains, Tullamarine, Lambton, Welshpool and Edwardstown.

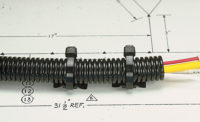

Because the company makes so many different cables for so many different customers, marking equipment is an essential part of its operation. Cables are printed at varying intervals, from simple number codes a few centimeters apart to long alphanumeric messages at much greater spacing.

Not long ago, the company found that printer downtime and reliability issues were impeding output and product quality. Printer breakdowns sometimes affected the quality of the marks, and rework was not always possible, leading to costly waste.

Bambach needed new printing equipment that promised to reduce downtime, cut waste due to coding errors, and eliminate rework. The new printers would have to:

- keep up with fast production lines.

- print clearly, using black or white ink, onto cables of various colors.

- accommodate cable diameters from 1 to 30 millimeters.

- handle a variety of substrates, including PVC, polyurethane and cross-linked polyethylene.

After comparing equipment from different suppliers, Bambach chose the Linx 7900 continuous ink-jet printer for its ease of use, excellent print quality, fast print speed, and ability to print on a wide range of cable sizes.

The Linx 7900 printer sits next to the extrusion line, printing onto cables as they are extruded. Printed information includes product identification marks, company branding, customer information (including logos, if requested), information relating to standards compliance, and serial numbers for traceability.

Michael Ng, operations manager at Bambach, says the new coders have eliminated rework and product wastage, resulting in large savings. The coders’ simple setup has also allowed Bambach to change over lines very quickly, increasing uptime. The coders work 8- to 10-hour shifts, five days a week, at speeds of up to 200 meters per minute.

“We get excellent print quality with these coders,” says Ng.

New ink system technology enables the printer to run for up to 9,000 hours or 18 months between maintenance checkups.

A key feature of the printer is its Linx Insight software. This remote Web interface allows users to monitor and control the printer through a Web browser, either via a PC or a smartphone. With a few keystrokes, an operator can start, pause or stop the printer; choose new printing information from a list stored in memory; and download messages from the PC to the printer. Users can also lock the printer keyboard to prevent changes being made on the line, which helps reduce coding errors.