Home » Keywords: » laser marking

Items Tagged with 'laser marking'

ARTICLES

Marking Metal Parts With Precision

Manufacturers have several options for precisely marking metal parts.

August 6, 2018

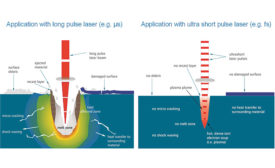

Code Marking Considerations

Production volume, durability, substrate and total cost of ownership are among many factors to consider when choosing a part marking technology.

December 12, 2017

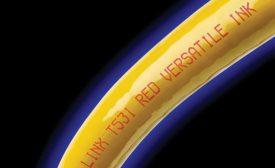

Options for Marking Wire and Cable

Lasers and continuous ink-jet printers create clear, long-lasting marks on wire and cable.

April 12, 2017

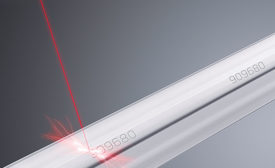

Lasers for Marking Parts

When the application calls for a high volume of parts to be permanently marked, a laser-based system is the best choice.

August 4, 2016

Get our new eMagazine delivered to your inbox every month.

Stay in the know on the latest assembly trends.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing