The “father” of the programmable logic controller (PLC), Richard Morley, recently passed away at age 84. After he invented the device 50 years ago, it revolutionized plant floors around the world. The PLC eliminated the need for hard wiring and spurred the development of flexible manufacturing.

A similar revolution is occurring in factories today. It’s called IO-Link or IEC 61131-9, a worldwide open standard communication protocol governed by the IO-Link Consortium.

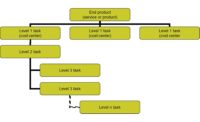

IO-Link has been hailed as the backbone of Industry 4.0 and the smart factory. It allows for the bidirectional exchange of data from sensors, actuators and other devices that support IO-Link and are connected to a master. IO-Link enables point-to-point communication and is based on widely used three-wire cable connections.

The IO-Link master can transmit this data over various networks, fieldbuses or backplane buses, making the data accessible for immediate action or long-term analysis via an industrial information system, such as a PLC or HMI.

However, IO-Link is not another fieldbus. It is a point-to-point communication protocol between a compatible IO system and a field device. Because IO-Link is an open standard, devices can be integrated in virtually any fieldbus or automation system.

“You can compare IO-Link with the USB interface,” says Elmar Buchler, Ph.D., factory automation strategic marketing manager at Balluff GmbH and head of the IO-Link Marketing Working Group. “Before USB, there were a lot of cables, connectors and interfaces, such as RS232, RS485 and PS2, to connect keyboards, printers and other devices to computers.

“That’s exactly the same with IO-Link,” claims Buchler. “There’s one cable to connect more than 6,000 devices from more than 170 device manufacturers worldwide.”

IO-Link includes a communication protocol that goes directly down to the sensor.

“Before, digital and analog sensors were wired to field-mounted bus-couplers or wired all the way back to the PLC,” explains Allen Tubbs, product manager for electric drives and controls at Bosch Rexroth Corp. “The data was then collected and distributed by one of those devices. Values were on-off or a single analog value.

“With IO-Link, data is provided on a serial communication channel that includes the sensor data, but also can provide much more information on the same wire,” adds Tubbs. “This allows for monitoring and adjusting of the sensor itself, both of which, to date, have been manual, at-the-sensor processes.”

IO-Link is different than other communication protocols that manufacturing engineers have relied on in the past.

“It allows for cyclic and deterministic process data, as well as for acyclic service data communication,” says Michael Kaspar, product manager for optical sensors at SICK AG. “It is designed to grant bidirectional access to device data for all devices.

“Its point-to-point architecture, which does not require addressing; the inbuilt service data channel, which does not influence the process data communication; and the IODD (IO-Link device description), which describes the IO-Link device entirely, make the difference,” Kaspar points out.

Big Benefits

IO-Link technology offers numerous benefits to manufacturers. For instance, it enables transparent, standardized communication between sensors and actuators.

“Having this communication allows devices to exchange parameter and status data between the sensor, actuator and the PLC,” says Kaspar. “Parameter data could, for example, be sensing range and switch point settings for a photoelectric proximity sensor or process diagnostics information provided by an inductive sensor.”

“IO-Link can help manufacturers reduce overall costs, increase process efficiency and improve machine availability,” adds Dana Holmes, global business development manager for sensors at Banner Engineering Corp. “The benefits of IO-Link are especially significant for assembly lines that experience frequent changeover and are severely impacted by extended or unplanned downtime.”

According to Holmes, there are several advantages to using IO-Link technology, including:

- Standardized and reduced wiring.

- Increased data availability.

- Remote configuration and monitoring.

- Extended diagnostics.

“All of these help manufacturers improve overall efficiencies and increase productivity,” explains Holmes. “The ability to gather device data from the sensor level is especially important, because it provides valuable insight into machine performance, process inefficiencies and more.

“Real-time remote monitoring of sensor status allows operators to address issues as they arise, and often resolve concerns before they escalate to line shutdown,” Holmes points out. “Performance and runtime data from IO-Link devices can also be used in overall equipment effectiveness calculations.”

“[IO-Link] allows sensors and actuators to carry out additional functions, such as remote parametrization and monitoring, thus enabling manufacturers to [shorten time-consuming] processes such as changeovers,” says Sandro Quintero, product manager for valve terminals and electronics at Festo US.

“This is very important in today’s market, since we can already see trends in individualization, which require smaller production batches,” adds Quintero. “In addition, commissioning is done faster thanks to ease of connections and software implementation.”

With IO-Link interfaces, engineers can determine if a device is behaving the way it should and predict malfunctions or avoid them by replacing the device at the right time.

“Troubleshooting time is greatly decreased and monitoring can be done remotely,” claims Quintero. “[For] device replacement, all parameters can be pushed to the new device from the PLC instead of having to commission it manually.”

“Installation and commissioning time are greatly improved,” notes Bosch Rexroth’s Tubbs. “With standardized cables and interfaces for all sensors, regardless of function, parts management becomes simpler and more efficient. Matching the cable to the sensor and application isn’t an issue, as the communication medium is the same for both digital and analog sensors.

“Additionally, sensors can be parameterized, meaning that instead of manually adjusting each sensor on repeat machinery, known parameters can be downloaded digitally to each sensor with known results,” Tubbs points out. “This reduces setup and commissioning time, [and aids] troubleshooting.”

IO-Link technology is growing rapidly and is becoming a de facto standard for smart sensing applications today. Indeed, it is considered to be an enabling technology for Industry 4.0 and next-generation manufacturing.

“Sensors and actuators have traditionally been a critical building block for automated systems, but their full potential can only be realized when all their information and capabilities can be tapped,” says Axel Rodriguez, smart sensing and safety system integration manager at Rockwell Automation Inc. “IO-Link enables this to happen.”

According to Rodriguez, smart devices provide much more information than the traditional on-off contact, enabling engineers to gain insight about their systems that was previously locked inside those devices. “This insight can allow them to reduce unscheduled downtime while helping to improve productivity and quality,” he points out.

“The biggest advantage of IO-Link is the capability to leverage existing wiring technologies, while still allowing the control systems to tap into the additional information available in the devices,” claims Rodriguez. “As sensors and actuators evolve, they are becoming smarter and more aware of themselves and their surroundings. This information can now be tapped at the source and moved all the way up the control system to enable ‘the connected enterprise.’”

In addition to helping manufacturers improve productivity and streamline operations, IO-Link offers numerous benefits to machine builders.

“The biggest advantage comes from the simplified wiring scheme of IO-Link devices,” notes Will Healy III, marketing management director at Balluff Inc. “We have seen machine builders reduce their wiring hardware and labor costs by 30 percent to 60 percent for sensors, outputs and controls.”

New Products

Manufacturing engineers can choose from a growing list of IO-Link components. For instance, at the recent Assembly Show in Rosemont, IL, Banner Engineering showcased several products equipped with the technology, including laser distance sensors, indicator lights and tower lights.

“Our IO-Link product offering is growing quickly and began with measurement products that were traditionally

available with analog outputs,” says Holmes. “New laser distance platforms, like our Q4X, offer IO-Link as an option. Smart LED-based indicators and tower lights are also a big area of growth for IO-Link capable products.”

Last month, Balluff unveiled the BML SL1 absolute magnetic linear encoder with IO-Link. It provides absolute position measurement over lengths up to 8 meters and with position resolution to 1 micron. The device is intended for applications where precise position measurement is required, such as linear measurement on X-Y tables or overhead gantries.

“The BML SL1 leverages the power of IO-Link to allow simplified integration of absolute linear position measurement to nearly any industrial control platform,” explains Scott Rosenberger, product marketing manager for measurement products at Balluff. “The sensor reports exact position data without requiring additional calculations for resolution or analog-to-digital conversion.

“Not only does the IO-Link interface greatly simplify the connection to the machine control system, it also presents opportunities for substantial cost savings by allowing numerous sensors to be connected to one IO-Link master, using standard unshielded sensor cables,” claims Rosenberger. “Plus, there is no need for dedicated, expensive absolute encoder interface hardware.”

“Balluff is the market pioneer in IO-Link, with a proven and installed technology base starting way back in 2009,” adds Healy. “Our IO-Link slave devices [include] RFID read-write heads, photoelectric sensors, color sensors, capacitive sensors, inductive sensors, magnetic field cylinder sensors, laser measurement sensors, linear encoders, light arrays, linear position sensors, inductive coupling technology, valve manifold controllers, analog inputs and outputs, discrete I/O for welding and robotic end effectors.

“Our approach to IO-Link includes a machine mount I/O strategy to reduce wiring complexity,” Healy points out. “The Balluff architecture connects all devices at the field level closest to production over IO-Link to enable smart manufacturing and simplify the building and maintenance of [production] equipment.”

Many other automation suppliers have jumped on the IO-Link bandwagon and plan to release new products next year, including Festo and Schunk.

“We are developing most of our next-generation devices with IO-Link capabilities,” says Festo’s Quintero. “[This includes] pressure sensors, flow sensors, position transmitters, proportional pressure regulators, vacuum generators and even stepper motor drives.”

During the first half of 2018, Schunk plans to come out with an IO-Link version of its PGN plus E gripper and the MMS 22 sensor line.

“After that, the whole product range of 24-volt actuators, including linear actuators, will be offered as an IO-Link version, in addition to the standard versions,” explains Markus Walderich, group manager for automation at Schunk Inc