Robot Integration and saving floor space

When utilizing a robot in any assembly application, saving on floor space and set up time are key to a successful integration. This can be achieved elegantly by using a rotary index table that has ability to mount said robot to a stationary center column. In doing this, you will cut down on the floor space required while fully integrating two independent automated pieces into one. This can all be achieved while being controlled independently or as an auxiliary axis to the robot. Motion Index Drives offers a vast range of fixed and programmable rotary index tables that can be adapted to accept any robot brand.

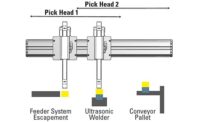

Linear Indexing: keeping process compact

In the consumer product industry, often multiple assembly processes must occur from start to finish. Consider a Ball point pen, for example. Simple as its design may be, it has numerous parts that must come together in a particular order. Then consider there is a process for each part! The pen is a fairly small product, but with a mechanism required for each part in the assembly process, the footprint grows as additional stations are added, leaving little floor space for future use. A simple solution: Automate your process in a linear fashion! Precision indexing a product linearly from process to process is an effective way to save floor space and streamline integration. The LFA precision link indexing conveyors engineered by Motion Index Drives provide high accuracy in X, Y and Z directions and can be manufactured as fully programmable systems or with a fixed indexing stroke.

7th axis robot transfers or tool slides

Process engineers are familiar with the advantages of using robot slides, or what some industries call 7th axis slides for material handling processes. In other applications, where welding and other processes are being performed on large, heavy parts that need to be transported to multiple stations, a tool slide can be utilized. The LazerArc ILM systems manufactured by Motion Index Drives offer high accuracies and are engineered and constructed to hold up to the harshest manufacturing environments. The advantages of changing between tooling fixtures and running different parts on the same line are just a few examples of how these custom engineered solutions are being realized for the future of manufacturing.

Lift and shift or Lift and rotate

Both lift and shift and lift and rotate precision indexing systems give a process engineer the ability to lift and move material, either linearly or in a rotary fashion. The lift and shift motion is achieved with a lift and carry system, or SP walking beam. For heavy loads that need transporting over distances longer than 1.0 meter, a Lift and Carry system is best suited for the job. A walking beam SP style unit would be used in a similar fashion, but is better suited for smaller loads with less horizontal stroke requirement. A lift and rotate indexer come in a large array of sized and is typically utilized for high speed, precision applications such as tool changing or lifting parts from one fixture nest to another at a specific degree of rotation. In situations where the lift and rotate stroke is known, and the application is fixed, it is advantageous to use a fixed cam lift and rotate unit. Once mechanically synchronized, integration cost and commissioning time are reduced, all while providing a robust solution requiring little to no maintenance.

Programmable cam indexers vs fixed cam indexers

Using a barrel cam indexer for any automated process provides many benefits including accuracy, repeatability and robustness to handle any size application. The RT series indexers by Motion Index Drives can be manufactured to have up to 108 stops. The fixed cam indexers offer a cost advantage over fully programmable versions and in their simplicity, save on total integration cost. Fully programmable tables boast an impressive list of features and benefits beyond zero backlash and high precision mechanical components. In addition, they can be programmed to act as an auxiliary axis to any brand of robot, or to switch between multiple programs on the same index table. This high degree of flexibility allows them to be repurposed easily between processes and programs, and all at the whim of the process engineer, making them a truly essential tool in the modern manufacturing space.

Motion Index Drives

(877) 978-1830