Liquid silicone rubber (LSR) injection molding is an industrial process that has been around for years. Its use has significantly expanded recently, especially in the areas of medical devices and wearable technology, as well as automotive, infant care and household goods.

LSR cures faster and offers properties not obtainable with traditional rubber materials, especially heat resistance, extreme low-temperature flexibility, chemical resistance, biological inertness, and an intrinsic capacity for reducing friction. The material’s expanded use has resulted in the development of new LSR process equipment, especially technology that optimizes LSR injection molding machines to provide the greatest value and ease of use. An example is the development of new closed-loop control systems, including those found in the Graco Fluid Automation F4 series.

LSR Basics

The basic raw material for silicone rubber is sand, or silicon dioxide. The material is processed into pure silicon metal. It is then reacted with methyl chloride, after which a range of processing steps is used to create a variety of silicon types, including liquid.

LSR is a two-component reactive chemical with a thick, almost paste-like consistency, which has been compared to peanut butter. The two components are usually shipped in separate containers. Some medical-grade silicones are shipped in small disposable plastic cartridges. The two components are mixed in a 1:1 ratio to produce a reaction. Accelerated by heat, the two liquids change to a solid rubber.

LSR injection molding is an inherently clean production process, because the component chemicals are sealed within a closed system. No ambient air contacts the parts until they are removed from the mold, eliminating issues with dust and moisture. This also improves part quality, because contaminants can diminish the cured rubber’s physical properties.

Many Industries Benefit from Use of LSR

LSR material technology is changing rapidly. Use of LSR is growing in both traditional rubber applications and those where traditional rubber materials had not previously been used. Key examples include medical devices, wearables, automotive, industrial, and even such home goods as bakeware and kitchen tools.

Medical devices – LSR’s inert qualities make the material ideal for many medical device types. LSR cures completely and quickly. This is especially critical when medical devices are placed in a patient’s body, because it means the device will not leach chemicals and cause potential adverse reactions. By contrast, latex, a material long used in the medical industry, does not fully cure during production, and can lead to adverse patient reactions.

Due to the material’s chemical makeup, it does not degrade until heated to very high temperatures – way higher than most other polymers could tolerate. This means it can handle sterilization processes, contributing to its effectiveness for medical and baby care uses.

A final (and critical) advantage is the ability to use LSRs to manufacture drug-eluding devices (DEDs). For example, hormones used in the NuvaRing contraceptive product are injected as an additive in the LSR dosing process. LSR DEDs can also be placed in pacemaker heart catheter leads, enabling the leads to introduce anti-inflammatory medication directly into heart tissue for improved results.

Wearable technology: Wearable fitness trackers, such as FitBit and Jawbone, are largely responsible for the expansion of the flexible wearables category. With its ability to handle both high and low temperatures, ultraviolet (UV), and ozone without degrading, LSR is a better fit than traditional materials for wearable technology used under constant sun exposure. Unlike other rubber, products manufactured with LSR are unlikely to cause adverse skin reactions when worn by users, even for extended periods of time.

Household goods: The inert nature of LSR makes it useful for bakeware and other kitchen goods. The consumer market is filled with kitchen products manufactured with LSR, from protective gloves and trivets to spatulas and barbeque brushes, and even cooking pans, where its non-stick properties are useful. These applications benefit especially from LSR’s high temperature resistance; the material is stable and food-safe even at very high temperatures.

Automotive: LSR-based products have also begun to be used in automotive applications, particularly windshield wiper blades and LED headlights. With windshield wiper blades, LSR’s greatest benefit is that it remains flexible throughout the product’s life. Traditional rubber materials continue to cure due to UV exposure and heat, gradually making the windshield wipers ineffective, while LSR does not. This greatly extends the product’s useful life.

In the case of LED headlights, reflectors and lenses are made out of special LSR grades designed for clarity and longevity. The reflectors are manufactured with additives that allow the LSR product to reflect back nearly 100 percent of light, amplifying the LED light. As a result, low-energy, long-lived LED bulbs can be as bright and effective as higher-energy, shorter-lived light sources. LED lenses are made with optical grade silicone, which offers glass-like clarity. The benefits of LED headlights made with LSR reflectors and lenses also make them suitable for traffic signals, streetlights, and other LED applications.

Industrial applications: In the electronics industry, LSR is being used for millions of parts, including connector seals, grommets, and strain relief devices. Offering resistance to extreme temperatures, UV and ozone, LSR also acts as an insulator or conductor, dependent upon material additives. On its own, silicone is a highly effective insulator, but can also serve as a conductor when manufactured with such fillers as carbon black.

LSR-based connector seals are often manufactured with an additive of red iron oxide to increase the product’s temperature resistance to 500 degrees. As new additives are created and physical properties of LSR products improve, the use of LSR for seal and gasket material will likely grow even further.

Optimizing the LSR Production Process

To achieve LSR’s myriad benefits for such a wide variety of applications, LSR injection molding machines must be optimized to provide the greatest value and ease of use.

While LSR equipment is similar in many ways to the plastics industry, many plastic tool makers try to manufacture LSR tools in the same manner as a plastic tool, which can lead to manufacturing failures. It is essential to use tool makers with a specific track record making LSR tooling. Also critical is working with an injection molding machine company that can assist with processing challenges, since successful LSR manufacturing requires that all components work properly together.

The most common pain points in LSR manufacturing are managing waste and controlling color changes and additives. Excess material is wasted because it is difficult to reclaim it due to such issues as air bubbles, loss of certification, and a lack of lot tracking. Color changes can pose production down time, because extensive cleaning processes between colors can take as long as four to six hours. In addition, control of color or additives is also a concern, especially controlling functional additives in the medical device industry.

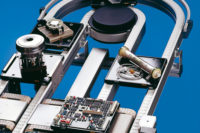

Both waste and increased additive control can be addressed through new closed-loop control system technology being developed. For example, the Graco Fluid Automation F4 series systems use a dosing valve and a high-resolution flow meter to provide a closed-loop control for third and fourth stream additives, such as color and medications. The system monitors and adjusts to ensure the additive is being dispensed in the appropriate amount. If there is an out of tolerance condition, the system stops production to prevent manufacturing bad parts.

In addition, controlling the flow of the two primary material components in a closed-loop system allows the machine to react to changes in the material viscosity and the presence of air bubbles. Operators can vary the ratio to ensure the correct amount of material is used.

The closed loop control of the two-component LSR’s dispense ratio is achieved by monitoring the material flow using high-resolution, helical gear-style flow meters. The helical gear uses multiple gear teeth to measure the flow in very small increments. Information from these flow meters is fed back to the controller, which operates the valve to alter the flow of material to the flow meter, forming the closed loop.

The increased number of measurements provides more assurance that the machine is running on-ratio to prevent manufacturing of bad parts. Closed loop control therefore significantly reduces waste and rework caused by off-ratio dispensing.

The new system offers a simple calibration routine that can be performed by the end user as necessary for a particular process. This can have a significant impact on product quality. The sample is collected and weighed, and the resulting data is entered into the advanced display module to calculate the current actual dispense ratio and calibrate the control system.

A variety of other controls help to monitor processes, which is important to reliably manage the LSR system for its entire lifetime. An example is the GCA (Graco Control Architecture), which provides longer life cycles than standard PLC products, and has a much faster response time than other control architecture types.

Overall, the new technology helps manufacturers reduce waste, ensure proper additive introduction, and control the operation of LSR dispense systems, leading to hassle-free production.

LSR at the Leading Edge

The LSR industry is in a state of rapid expansion, and continues to offer new and improved materials to replace older technologies with longer-lasting, more effective solutions. Improvements to LSR physical properties for individual applications means LSR will likely continue replacing traditional rubber materials in existing industries – and probably move into others. With the advanced LSR dispense and production technology currently on the market, the manufacturing of LSR products can be managed to minimize issues and take full advantage of this material’s wide-ranging potential.

References

Getting Started in LSR: Understanding the Materials, Part I, Plastics Technology, June 2010