Despite the proliferation of robotics and the Industrial Internet of Things in many aspects of manufacturing, Industry 4.0 initiatives have so far been only marginally applied to fluid dispensing processes.

While dispensing technologies have offered some level of network connectivity, it was rarely comprehensive enough for complete remote management. Several obstacles have prevented the application of Industry 4.0 to dispensing operations. These include:

- absence of direct communication between equipment.

- inadequate data capture.

- lack of in-place troubleshooting.

- tedious programming.

- no visibility of dispensing parameters.

As companies move toward Industry 4.0, they need dispensing systems that can be fully integrated with shop-floor networks and production systems, meaning complete remote management capability. This means providing two-way communication between the PLC and the dispensing hardware.

Current approaches for integrated systems provide one-way communication between the PLC and the hardware with limited capabilities. A production manager must visit each dispense unit to set it up, a time-consuming exercise. Additionally, for process management, no data is captured from the dispensers, so a particular assembly cannot be linked back to a specific dispenser.

Current dispensers also do not offer troubleshooting functionality. Most of the time, it is not clear whether the issue is with the dispensing equipment or with the process setup. Without remote monitoring capability, the operator has no way of knowing the settings on the dispenser. To determine if the settings are in line with the application requirements, the operator would need to visit each unit.

Repeatability and Accuracy

Whether applying solder paste, adhesive or lubricant, the dispensing equipment must be reliable, accurate and repeatable. Depositing the right amount of fluid is vital to the integrity of the assembly and keeping downstream production moving. If too little fluid is applied, the parts will not bond properly. If too much is applied, the assembly will take longer to cure.

Accuracy and repeatability depend on more than just the dispensing valve, but also on the peripherals. Components such as syringe barrels, adapter assemblies, pistons, tips and caps, must be designed to meet the requirements of the specific fluid and application.

To achieve the highest level of performance from dispensing systems, several requirements must be met:

- Each component of the dispenser should be designed as part of a complete, integrated system. This will improve yields and reduce costs by producing the most accurate, repeatable fluid deposits possible. Mixing and matching components from different systems or suppliers is a recipe for diminishing performance.

- Dispensing components should always be used as single-use consumables. Precision syringes, pistons and tips are manufactured to exacting tolerances. Any residue from prior dispensing operations will degrade future dispensing performance. Once the piston reaches the bottom of the barrel, both the barrel and the piston should be discarded.

- Maintaining precision and shot-to-shot repeatability in dispensing starts with quality manufacturing of the components. For best performance, all components should be certified as being free of silicone mold-release agents.

- The ability to set the time, pressure and other parameters for a dispensing application ensures the right amount of fluid is placed on each part.

Transforming fluid dispensing from a manual procedure to an automated process provides cost savings from labor and fluid waste. More importantly, it can deliver a higher level of repeatability, accuracy and traceability.

Dispensing and Connectivity

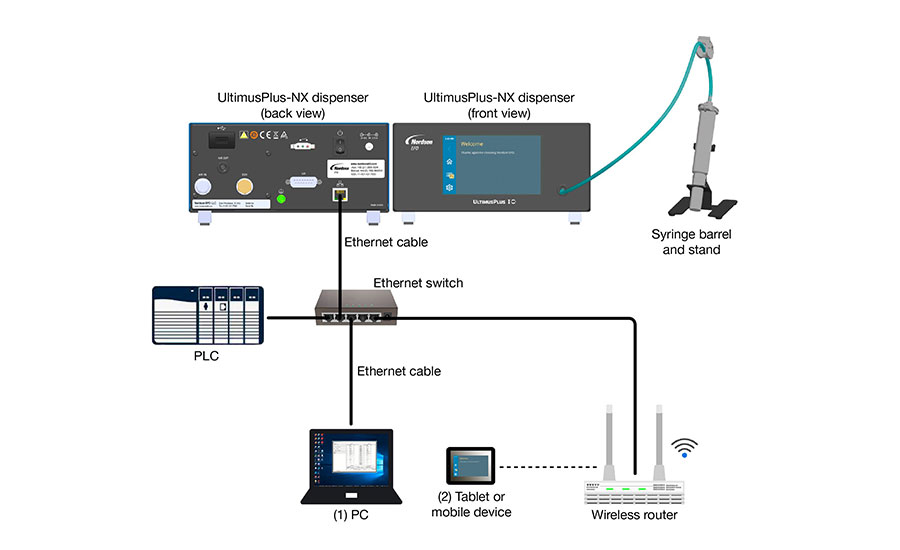

For the first time, engineers can now program, monitor, perform diagnostics and access process data from multiple fluid dispensers directly through a PLC, or with a web interface from a central computer, tablet or mobile device. This is a major breakthrough for managing processes with multiple fluid dispensers.

Newly released from Nordson EFD, NX technology supports smart factory connectivity with a comprehensive suite of functionality for centralized remote control of all dispensing parameters via Ethernet. Compatible with both benchtop dispensers and robots, NX technology improves process control, diagnostics and operational efficiency in dispensing operations.

NX technology is based on TCP/IP (transmission control protocol/Internet protocol), a set of rules and formats that govern the communication between devices on a network, allowing two or more devices to exchange data. TCP/IP is a widely known protocol, used to create Ethernet-based networks.

NX technology has been engineered for application with Nordson EFD’s UltimusPlus fluid dispenser and 7197 PCP-DIN-NX volumetric pump controllers. The technology gives engineers complete remote management of their fluid dispensers, or controllers, permitting their processes to operate in two-way communication with PLCs.

This protocol is all about binding manufacturing processes into an easily understood platform. NX connects all dispensing processes together for programming, operation, process monitoring and troubleshooting.

The technology enables engineers to program dispensing equipment directly from a central PLC, PC or mobile device. There is no need to visit each dispenser individually. The technology permits changes to dispensing parameters on the fly at any point.

NX technology features line, volume, weight and time dispense modes to provide versatility for a range of applications. Information is entered on the NX client application in the same way that integrators will enter that information on a PLC or PC client application while setting up the network. The client application allows remote familiarization with data input.

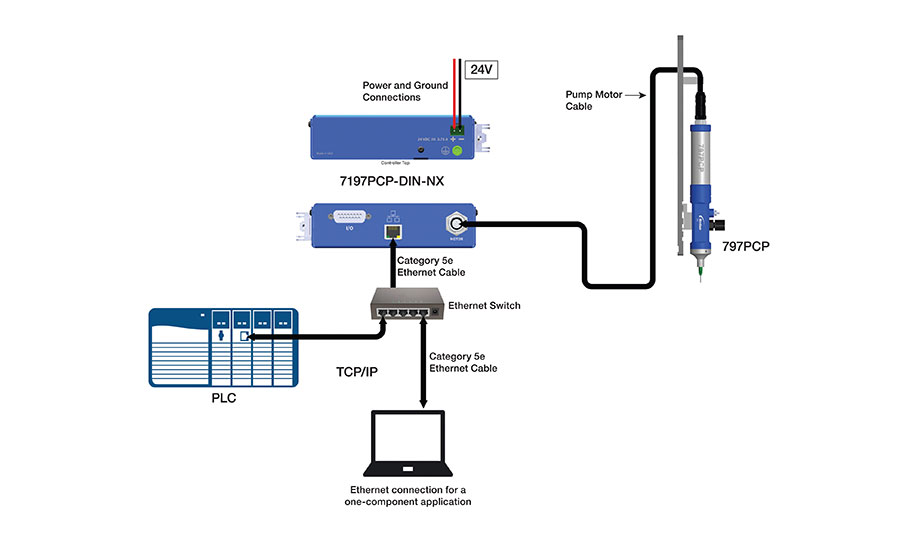

The 7197 PCP-DIN-NX controller allows direct communication with a PLC or other controller using TCP/IP via Ethernet. Photo courtesy Nordson EFD

Downloading Dispensing Data

NX also delivers improved process documentation, with the ability to download dispensing data remotely and directly to an FTP site. The system captures data on each dispensing cycle, including pressure, vacuum and time settings, as well as the time and the date of each operation.

This is particularly important in an FDA-approved process, where it is imperative to have confirmation that the PLC is connected to the correct dispenser. UltimusPlus with NX capability can direct a PLC to assign a unique status IP address that can be called upon to confirm that the PLC is communicating with the correct dispenser. As an extra layer of protection, the PLC can call upon a serial number of the dispenser to ensure it is the right dispenser.

For the first time, engineers can have a comprehensive set of dispense data for process analysis. They can link an event to a particular application, whether the process is based on a PLC or PC.

In addition, engineers have ability to remotely troubleshoot from nearly any device. NX technology can assist operators to identify where the problem may lie, for example with the dispenser hardware or with the network.

For the first time, engineers can now program, monitor, perform diagnostics and access process data from multiple fluid dispensers directly through a PLC, PC or mobile device. Photo courtesy Nordson EFD

Connected Technology

The UltimusPlus was designed to make dispensing easier and more efficient and to maintain better control over process parameters. The machine features a touch screen control; automated pressure regulation with operator lock-out; bar code scanning; memory storage of project parameters; digital dispense log; sleep mode; and flash drive program download.

The UltimusPlus was designed to make dispensing easier and more efficient and to maintain better control over process parameters. Photo courtesy Nordson EFD

The machine is available in two models. UltimusPlus I features a pressure regulator covering 10 to 100 psi and is ideal for dispensing a range of fluids. UltimusPlus II features a pressure regulator covering 0.3 to 15 psi, which provides greater control when dispensing thin fluids.

Nordson EFD’s 7197 PCP-DIN-NX controller provides centralized control of 797 PCP Series volumetric pumps. The controller accommodates both one- and two-component fluids and provides volume accuracy and repeatability within less than 1 percent. It has the same feature set as the standard 7197 PCP-DIN controller, but with the added functionality of being network capable.

The 797 PCP Series pump has a modular design based on the progressive cavity principal. Its core components—a rotor and a stator—form a perfectly sealed metering chamber. Its continuous seal prevents shear, pulsation and squeezing of fluid. This makes the 797 PCP system ideal for dispensing abrasive pastes, filled materials and UV-cure adhesives.

The pump dispenses an exact volume of fluid as small as 0.01 milliliter per revolution. It is available in three sizes—0.01, 0.05 and 0.15 milliliter.

NX technology is important for process monitoring with the pump. Using a PLC or PC, engineers can record and download process feedback and verify rotor movement, which tells the operator that the progressive cavity pump is running. For example, if the pump stops running, the operator can troubleshoot before the interruption greatly affects productivity. This feature is important for dispensing two-part epoxies and thermal interface materials.

The controller’s small size makes it easy to mount inside machine cabinets.

For more information, visit www.nordson.com.

ASSEMBLY ONLINE

For more information on adhesive dispensing, visit www.assemblymag.com to read these articles:

Dispensing for Automotive Applications

The Evolution of Automated Dispensing Technology

Dispensing Challenges and Solutions