In November 1976, entrepreneur Robert L. Luddy started Atlantic Fire Systems in Raleigh, NC, to sell automatic dry chemical fire systems to restaurants and industry. Sales for the first full year in business reached $297,000.

Luddy soon developed a relationship with James Maynard and Bill Carl, co-founders of the Golden Corral restaurant chain, which started in nearby Fayetteville, NC. In 1978, Ben Maynard, James’ father, suggested to Luddy that he open a sheet metal shop to manufacture ventilation hoods and integrate the fire system. Sales reached $1 million in 1979.

CaptiveAire is one of the nation’s leading manufacturers of commercial kitchen ventilation systems, with annual sales of more than $500 million. Photo courtesy CaptiveAire

Two years later, Luddy formed a separate company, CaptiveAire, just for the ventilation business. Today, that company is one of the nation’s leading manufacturers of commercial kitchen ventilation systems, with annual sales of more than $500 million. The company’s kitchen ventilation packages include hoods, exhaust fans, electrical controls, direct-fired heaters, grease duct systems, fire suppression systems, grease filters and utility distribution systems. CaptiveAire’s clients include independent restaurants, national chains, and other public and private institutions.

The company has more than 1,300 employees in its network of 100 sales offices in the U.S. and Canada and six manufacturing plants located in North Carolina, Iowa, Oklahoma, California, Pennsylvania and Florida.

CaptiveAire uses a variety of methods to assemble its products. One of them is stud welding, in which a metal stud is joined to a metal workpiece by heating both parts with an arc of electricity. A key factor that differentiates stud welding from other fastening processes is that the fastener is attached without penetrating the workpiece or marring the other side. This is a major benefit for CaptiveAire, since the process seals ventilation systems and eliminates the possibility of leakage and areas for bacteria or impurities to build up.

At CaptiveAire, stud welding was initially a labor-intensive manual process. In addition, workers often had difficulty maintaining the vertical position of the studs. To solve the problem, CaptiveAire contracted Spectrum Design LLC in Franklinville, NJ, to develop a custom, gantry-based CNC system that would automatically position and weld the studs.

CaptiveAire operates manufacturing plants in North Carolina, Iowa, Oklahoma, California, Pennsylvania and Florida. Photo courtesy CaptiveAire

Advantages of Stud Welding

Stud welding is ideal for the food industry since it eliminates sources of contamination, as well as holes for potential leaks. It improves the strength and appearance of the parent material, since studs are surface-mounted on one side of the workpiece without holes or reverse side markings. Stud welds do not loosen, because they are fused to the parent metal.

CaptiveAire has long used capacitor discharge stud welding to produce stainless steel oven hoods. The studs have a small tip that extends from the base. When triggering energy stored in capacitors is discharged, the weld is produced. Peak currents vaporize the tip, drawing a precisely timed arc that instantly melts the full diameter of the stud and the same-sized area on the parent metal. Spring-loading forces the molten fastener against the surface of the workpiece, and the weld is completed in about three milliseconds.

“We were very pleased with the benefits that stud welding provides to our customers, but had concerns with the manual welding process. One problem was the difficulty in positioning the studs against the 18-gauge parent material,” explains Luke Wilson, quality process engineer at CaptiveAire. “The welder eyeballed the stud to put it into position, and it was easy to place it at an angle. If the stud is not perpendicular to the material, then the nut that is later fastened to the stud can put a dimple in the mating material. Another concern with the previous process was that it took a considerable amount of labor.”

CaptiveAire approached Spectrum to automate the stud welding application. The company has years of experience manufacturing custom equipment. Combining state-of-the-art 3D design software and in-house manufacturing capabilities, Spectrum has designed a variety of automated systems for assembly, welding, inspection, packaging and palletizing.

For the stud welding project, Spectrum partnered with International Welding Technologies Inc. (IWT) in Lindenwold, NJ, a leader in capacitor discharge stud welding technologies, including handheld and fully automatic systems. IWT is unusual in the stud welding business in that it makes both manual and automated equipment, and it makes a complete line of fasteners. It is the largest producer of automated stud welding systems in the United States and the only supplier that makes its own welding heads and auto-feed fasteners, which is critical to controlling the quality of the finished product.

“Several years ago, we recognized the benefits of automating the stud welding process,” says Neil Wilkinson, general manager of IWT. “Originally, we built our own CNC machines in-house. But, as demand increased, we needed a reliable, off-the-shelf positioning base that could easily support the stud welding application.

“An important consideration in selecting a supplier was the ability to provide the multiple I/O needed to drive our capacitor discharge power supplies,” he continues. “We make everything from very simple machines with a single feeder bowl and one head, to machines with three weld heads supported by six feeder bowls. Each weld head and feeder bowl needs a signal from the control system to make it work.”

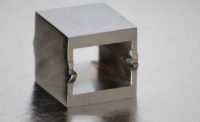

CaptiveAire uses a variety of methods to assemble its products, including welding. Photo courtesy CaptiveAire

Cartesian Robot Is Key to Success

IWT worked with Isel USA Inc. in Hicksville, NY, to develop a Cartesian robot for the system. The robot provides the I/O, automated operation, accuracy and speed required for the stud welding application. Every stud is perfectly positioned by the robot before welding. The only labor required is loading the machine and turning it on.

“Isel USA met our challenge by providing a breakout board with their gantry systems that provides either 16 or 32 IO,” says Wilkinson. “We connect these I/O to the various devices on our machine and control them through commands in the CNC program.”

For example, one command tells the robot to bring the head into position to make the weld. Other commands advance the weld head, fire the head, and turn off the weld head.

“Isel’s ability to control all of our equipment was an enormous advantage and one of the main reasons that we selected their gantry systems,” says Wilkinson.

Isel’s Cartesian robots are available with two to six axes of motion. They are ideal for CNC or automated work cell applications, such as welding, dispensing, drilling, milling, and test and inspection. They can be supplied as mechanics only or a complete system, including motors, controls, cabling and software. Travels range from a few inches to several feet. Controls are available for stepper motor or servomotor technology. Options include safety enclosures, light curtains, rotary axes and vision systems.

For the CaptiveAire application, the gantry system is equipped with ballscrews on all three axes with closed-loop servomotor drives that provide an accuracy of ±100 microns per 300 millimeters and a repeatability of ±100 microns. The robot also provides a speed of 152 millimeters per second, which is fast enough to achieve high production rates. Off-the-shelf CNC programming software controls the motion of the robot and issues commands to the welding system. Easily modified VBscripts and servo-automation-control subroutines can be developed, saved in the computer, and referenced to the panel being welded. These can then be recalled whenever the various panel configurations are required.

The robot can travel 60 inches on one axis and 120 inches on the other. All axes are provided with a home-reference switch and far-end limit switch. Each axis is provided with two double-slide linear rails and four double bearing blocks.

The X-axis bearings and drive screw are mounted below the work surface to protect them from dust and debris. The X-axis has an aluminum dust cover, and plastic lips provide protection against contaminants. Heavy cast aluminum side plates support the Y-axis and provide increased stiffness for positioning and cutting applications.

CaptiveAire employs some 1,300 people nationwide. Photo courtesy CaptiveAire

The system comes complete with electronics, cabling, motors and software, so the end user has a complete solution from a single source, eliminating the cost and frustration of dealing with multiple vendors.

Spectrum worked with IWT engineers to design a special fastener to address the concerns with reverse marking on the application. IWT’s cold-heading division quickly developed various fastener tip configurations that could then be tested for weld strength and reverse side marking. The company researched the CaptiveAire’s requirements and tailored the material properties of the fastener to provide optimal performance.

The stud welding process illustrates the advantages of working with companies that supply welding heads, CNC machines and fasteners. The first machine delivered to CaptiveAire uses a bottom-load head, in which the fastener is loaded into the bottom of the welding head and an auto-feed head. It has two heads for different types of studs. The stud welding system program moves the head to a point and moves the first or second head into position before firing.

“We have seen substantial improvements by automating stud welding with the CNC machines,” says Wilson. “Our operators simply load a workpiece and run the program. Then, while the machine is running, they can move to another task.

“The quality has been consistently excellent with studs positioned exactly perpendicular and no blemishes on the opposite side of the parent material,” he continues. “We are so happy with our first CNC stud welder that we recently purchased four more automated welding machines to put in each of our four other manufacturing facilities.”

For more information on Cartesian robots and motion control technology, visit www.isel-us.com.

For more information on stud welding technology, visit https://iwtmarketplace.com.

For more information on custom automation, visit https://spectrumdesignllc.com.

ASSEMBLY ONLINE

For more information on welding and Cartesian robots, read these articles:

Cartesian Robot Goes With the Flow

Arc Stud Welding

Cartesian Robot Doubles Output of Solar Lego Modules