According to ASSEMBLY magazine’s annual Capital Equipment Spending Survey, 38 percent of U.S. assembly plants will purchase electric or pneumatic fastening tools in 2024.

If fastening tools are on your shopping list, then The ASSEMBLY Show South is the place to be! Here, you’ll find dozens of suppliers offering cordless nutrunners, pneumatic screwdrivers, screwfeeders, digital torque wrenches and other fastening tools. Here’s a taste of what’s on the floor.

Click on the headings below for product information.

The HIOS BLG7000-BC2-GT smart electric screwdriver reduces errors and rework costs in assembly applications that require 2 to 5 newton-meters of torque. This ergonomic tool is available with either a handle or a stand. The screwdriver is powered by a brushless motor for cleaner operation and less maintenance.

Screwdriver settings can be changed via PC or PLC. When fastening several screws directly into a workpiece, it will automatically learn the number of rotation pulses from fastening start to seating. With a built-in screw counter, engineers can set the number of screws from one to 99. The remaining number of screws is counted down. Data can be collected and centrally managed in the cloud.

ASG, Div. of Jergens Inc.

https://asg-jergens.com

The XTCA torque and angle control system provides full control of the entire fastening process. Engineers can easily set up multiple tightening parameters, such as speed, time, thread, direction, torque and angle directly on the user friendly, touch-screen HMI. Engineers can create multiple jobs for different assembly stages and quickly switch between jobs dynamically. Tightening data can be transferred out using the built-in Ethernet Module via Modbus TCP protocol. Engineers can track and analyze fastening data to identify trends and make informed decisions about their processes.

Delta Regis Tools Inc.

https://deltaregis.com

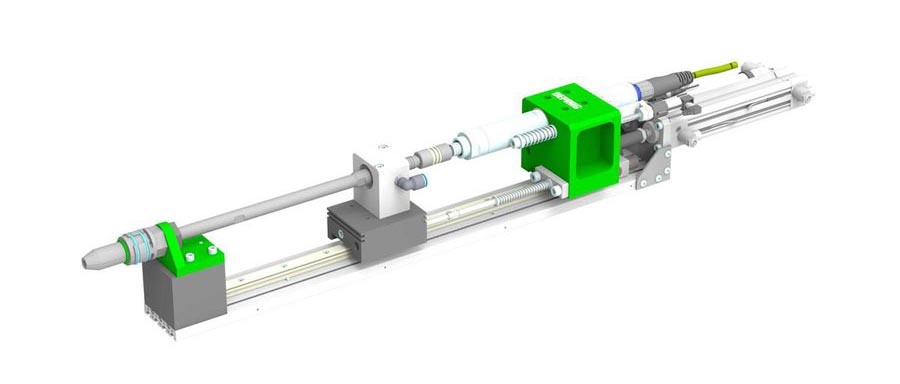

Automatic screwdriving modules are available in various configurations to meet the needs of any application. The modules have a compact, robust design and simple connection ports to facilitate integration into automated assembly systems. Each screwdriving spindle is equipped with a quick-change-chuck that allows bits to be changed quickly.

The newest module has been designed specifically for assembling EV batteries. The module is equipped with special ceramic and synthetic parts to electrically isolate the driver and protect against voltages of up to 1,000 volts. Available in single or multispindle versions, the module has special gripper jaws to avoid dropping the screw onto the workpiece and causing a short-circuit. A gentle screwfeeder and a vacuum port at the drive head keep particulates out of the assembly. The module meets ISO 6469-3 and DIN EN IEC 60900 requirements for electrical safety.

DEPRAG Inc.

www.depragusa.com

ESTIC has added the Master Interface (MIF) Cordless Wi-Fi-based architecture to its cordless torque tool lineup. This technology enables up to 10 cordless nutrunners to be paired with one controller.

The MIF can communicate on both the 2.4 and 5 gigahertz frequencies. The MIF features a dynamic touch screen interface for easy navigation, programming and configuration. The MIF will offer many forms of communication to fit seamlessly into an existing or new line. These include Open Protocol, Toolsnet and Ethernet IP.

ESTIC has also updated the design of its cordless tools. This update raises the upper torque range of its pistol-grip tool to 50 newton-meters, making the tool ideal for interior fastening applications in automobile assembly. The maximum torque output of the company’s right-angle cordless nutrunners is 100 newton-meters.

ESTIC America Inc.

www.estic-global.com

AccuTec programmable cordless clutch tools come in pistol-grip and right-angle versions. These lightweight, ergonomic tools are accurate and repeatable with easy-to-set controls. The tools are driven by FEIN’s powerful, brushless PowerDrive motors, which are built in-house.

Two lines are available. Both are suitable for hard and soft joints. Series ASM 18 consists of three pistol-grip models covering a torque range of 0.5 to 12 newton-meters. Speed can be set from 110 to 1,200 rpm. Series ASW 18 consists of six right-angle models covering a torque range of 1.2 to 60 newton-meters. Speed can be set from 20 to 1,100 rpm. Nine angle heads are available to match any application.

FEIN’s parameter control system enables engineers to set the direction of rotation, angle of rotation, and tool speed. The latter can be an exact setting or a percentage of the tool’s maximum speed.

FEIN Power Tools Inc.

https://fein.com

The E-torc Q electronic torque wrench has powerful software for intuitive parametrization, recording, graphic evaluation and archiving of tightening data. This intelligent wrench is suitable for use in quality assurance, process optimization, research and development. Three models are available, covering a torque range 10 to 300 newton-meters. The tool measures torque; torque and angle; loosening and tightening; and further tightening. A 4.3-inch color touch-screen display shows fastening operations directly on the wrench. Data transmission is via USB mini interface or WiFi. The tool has a rotating aluminum housing with an ergonomic handle. It is tested to the DIN EN ISO 6789:2003 Type I Class C standard.

GEDORE

https://us.gedore.com

Ergonomic Tightening Systems (ETS) technology is available as an option for the QX Series of cordless fastening tools. ETS technology minimizes the reaction force of the tools, while still providing the benefit of transducerized accuracy and control. The tools have optional wireless functions to report data back to the plant network. With that information, facilities can gain meaningful insights into their fastening processes and implement actions to improve quality and increase productivity. The cordless tools are flexible and portable, offering all the benefits of a closed-loop “smart” tool.

The controller for the tool’s motor uses an algorithm that essentially mimics the action of a pulse tool or impact tool, significantly reducing the average force experienced by the operator during the tightening process.

In addition to the standard direct-drive mode, each tool configuration can be independently programmed to use one of the three available ETS modes. Ergonomic mode, with the lowest energy pulses, is ideal for hard joints or when arm, wrist or tool angles are most difficult. Performance mode, with medium energy pulses, is the best all-purpose mode. Productivity mode, with the highest energy pulses, is the fastest mode. It’s best for soft joints or when high production rates are required. In the standard direct-drive mode, the ETS modes are disabled and the tool behaves like any DC electric tool.

Ingersoll Rand

https://powertools.ingersollrand.com

The cerTEST inspection system and the caliTEST-B calibration device enable manufacturers to perform standard-compliant testing and calibration of torque tools.

CerTEST allows mobile testing in a range from 0.2 to 500 newton-meters with up to four integrated fastening simulators. Fastening tools can be tested in accordance with standards such as VDI/VDE 2645 Sheet 2, VDI/VDE 2647 or DIN EN ISO 5393 directly on the assembly line.

CaliTEST-B is a calibration device for torque wrenches or tools with an effective length of up to 1,320 millimeters. Thanks to individually usable sensors, tools can be calibrated in a range between 0.2 and 1,000 newton-meters in accordance with DIN EN ISO 6789. The user-friendly software guides users step by step through the process. It saves different measurement settings and histories, and it automatically creates test reports.

Kistler Instrument Corp.

www.kistler.com

The PTT is a handheld torque analyzer for calibrating and testing screwdrivers, wrenches and power tools. Highly portable and user-friendly, this battery-powered analyzer can be carried directly to the assembly line to spot-check tools as part of a QA program or used at assembly stations for quick and easy tool validation and calibration, allowing operators and engineers to have maximum confidence in their tools. A torque sensor is needed to operate with the analyzer; the instrument does have a built-in internal transducer.

Mountz Inc.

www.mountztorque.com

The De-Riveter is a modified version of Orbitform’s standard impact riveting equipment, incorporating specially engineered tooling to remove rivets efficiently and precisely. Designed initially for a sporting goods manufacturer seeking technology to repair protective padding products, the De-Riveter can be used in a variety of applications, such as brake manufacturing and repair facilities. This versatile tool seamlessly removes brake pads from calipers.

Orbitform

www.orbitform.com

Replacement cables are available for DC electric nutrunners from a variety of OEMs, including Atlas Copco, Cleco, Stanley and Bosch Rexroth. Available with short lead times, these replacement cables are highly flexible, cost effective and durable. Cables can be ordered with custom lengths. Sahajanand can also repair or refurbish old or damaged cables. Booth 543

Sahajanand Impex Pvt. Ltd.

www.sahajanand.com

The 1350 Series TD digital screwdriver measures torque and angle. It is compatible with the Global 400 and Global 400mp controllers, and it meets or exceeds the requirements in the ASME B107.300-2010 and ISO 6789 standards. Clockwise torque measurement is accurate to ±2 percent of the indicated value at 20 to 100 percent of rated capacity. Counterclockwise torque measurement is accurate to ±4 percent.

Two models are available. One covers 4 to 80 inch-pounds; the other covers 5 to 100 inch-ounces. All torque and angle settings are set through the controller. The parameters cannot be set using the buttons on the tool, preventing inadvertent changes. The tool is available in a female hexagon version, as well as a male square drive version.

Torque and angle monitoring protects against double hits. If a fastener reaches torque without the required degrees of rotation, the fastener is rejected as noncompliant. Torque and angle functionality can also alert the operator if a gasket or washer is missing because it shows changing joint conditions.

The backlit display is visible when torque is applied. It can be seen from any angle. The light band on the driver turns yellow as the fastener nears target torque. When the target torque is achieved, the light turns green and the driver beeps and vibrates.

Sturtevant Richmont

www.srtorque.com

The CES-G is Tohnichi’s smallest digital torque wrench. Two models are available, covering a torque range of 0.5 to 10 newton-meters. A bright LED display allows assemblers to see results from various angles and in dark places. Engineers can output memory data via USB for management in Excel. By installing an optional Bluetooth module, tightening and inspection data can be transmitted wirelessly to a PC.

Tohnichi America Corp.

www.tohnichi.com

The DuPas GWC Series of cordless high-torque pistol nutrunners offers to 12 to 25 times the speed of comparable tools. The tools cover a torque range of 50 to 2,500 newton-meters and a speed range of 35 to 700 rpm. These current-controlled tools can measure torque in both newton-meters and foot-pounds. Fastening data can be transferred via WiFi to a DuPas receiver or via USB to a PC. The tool stores data for 5,000 run-downs, including date and time, torque value, and tightening result (OK or not OK). A lock mode eliminate unauthorized changes to the tool settings.

TorqTec

www.torqtec.net

The C50 controller for automatic screwdriving systems measures the torque, angle and depth of each screwdriving operation. It interfaces with manufacturing execution systems via open interfaces (Profibus, Profinet, Ethernet and Digital). It generates and documents performance results for record-keeping and compliance with each assembly’s process parameters.

The C50 also monitors gradient torque to provide detailed records of the rate of change between torque, angle and depth parameters. By monitoring this information, engineers can consistently achieve the required clamp load at the specified depth.

Some 255 selectable screwdriving programs are available. Custom programs can be created via an open interface. Fastening sequences are visualized on an optional Touch-Panel or a Windows-based computer. Detailed information about screwdriving curves and characteristics can be output. All process signals can be represented on any abscissa. The last 1,000 curves are stored in the controller, and up to 10 curves can be superimposed in visualizations. Options for system diagnosis, log book, backup, and help functions are also available.

WEBER Screwdriving Systems

www.weberusa.com