Home » Keywords: » Overall equipment effectiveness

Items Tagged with 'Overall equipment effectiveness'

ARTICLES

Uncovering Hidden Capacity Using OEE

By monitoring OEE, assemblers can reduce process variability, changeover times, overtime expenditures and capital investments.

October 20, 2017

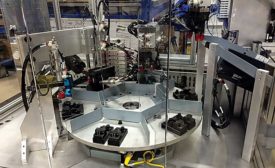

Bullet-Proof Automated Assembly

A system that runs like clockwork doesn’t happen by accident.

September 8, 2016

Get our new eMagazine delivered to your inbox every month.

Stay in the know on the latest assembly trends.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing