|

|

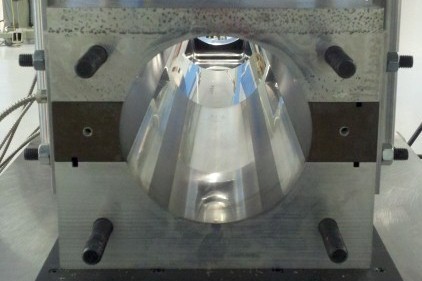

The work cell features preform, liner and harness assembly stations. Photo courtesy Nammo Composite Solutions |

To meet this high demand, Nammo Composite Solutions has developed an automated work cell that makes composite parts by combining resin transfer molding (RTM) with one-piece flow. Equally important, the work cell performs pre-production grit blasting of incoming metallic liners and permits easy installation and co-curing of complex electrical wiring harnesses.

The U-shaped work cell encompasses nearly 2,500 square feet of streamlined floor space and features preform, liner and harness assembly stations. To determine the best layout for product flow in the work cell, Nammo developed a 3D CAD model of its entire 67,000-square-foot shop floor.

In the RTM process, dry fabric preforms are built over metallic mandrels and inserted into matched metal molds for through injection of liquid resin. The molds permit the integration of a metal liner and a flexible electrical wire harness. Nammo likes RTM because it provides dimensional control over fully tooled part surfaces and shape molding of product so it requires minimal finish machining.

One piece flow uses single-cavity molds rather than multicavity molds. Single-cavity molds allow faster production of composite launchers and ensure their supply always meets the quantity demand of the next step in the manufacturing process.

In contrast, composite parts produced with a multicavity mold must cure in a batch-style sequence. This process willoften result in the incoming material bin being overloaded prior to a subsequent production step (i.e., bonding, painting, part marking, and inspection). The process also is more costly, as piles of work must be stored at the subsequent work stations.

Two other benefits of using single-cavity molds are increased worker safety and less scrap. Safety is improved because the single-cavity mold is much lighter and smaller. The potential for scrap is only limited to one part, rather than an entire batch, if something were to go wrong in the cure or resin-injection process.

During production, molds are shuttled twice within the work cell. First, they are moved from room-temperature preform, liner and harness assembly stations to elevated temperature cure and post-cure areas. Then the molds are brought back to room-temperature conditions for part demolding and mold cleaning.

Multiple heated platen presses control the closure of the molds and temperature ramping. Designed and built by Nammo’s engineering team, the presses are linked to a conveyor oven for post curing and cooling of the molds.

Up to 500 pounds of resin is housed in a central storage station and fed to each press via automated precision dispensing, resulting in rapid yet efficient movement of the 2.25 pounds of resin to each injection station. Bar coding is employed to reduce the amount of shop floor paperwork that is collected for part traceability.

Integrated software records the cure cycle, tool temperature and vacuum (during the resin injection sequence) for each component. This data can be downloaded for storage and analysis.