Last summer, Renault hit the start button on a new, highly automated line to assemble motors for electric vehicles at its historic factory in Cléon, France.

Renault has invested $664 million in the factory since 2018 to automate assembly of electric motors and other EV components. When it reaches full capacity next year, the plant will be able to produce more than 1 million electric motors annually. Half the factory’s output will go to battery electric vehicles, while the other half will be installed in hybrid vehicles.

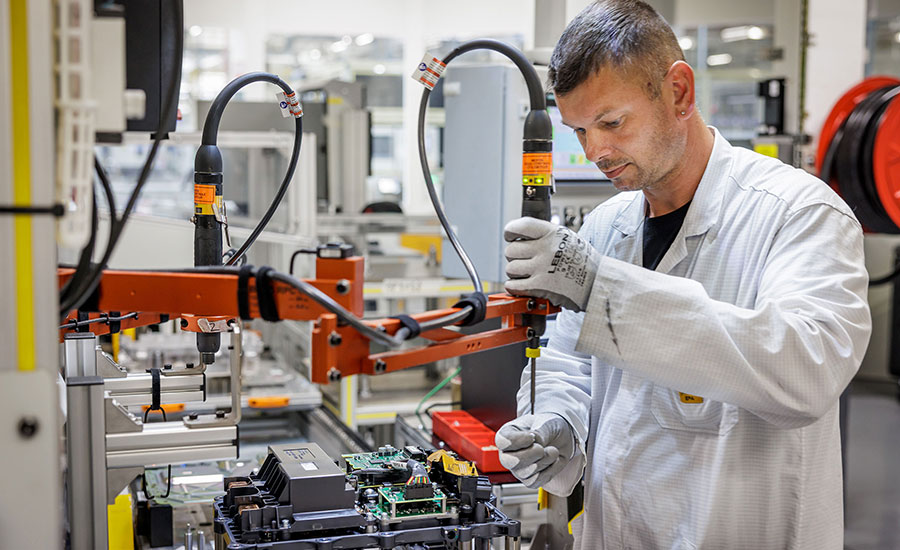

Since June 2022, the plant has added some 100 new employees to a workforce that already totaled more than 3,000 people.

Since June 2022, the Cléon plant has added some 100 new employees to a workforce that already totaled more than 3,000 people. Photo courtesy Renault Group

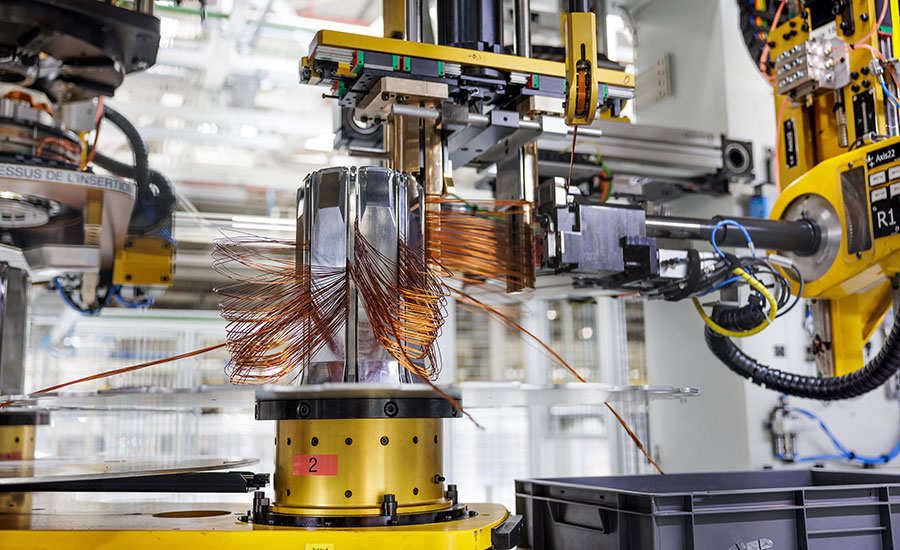

The first motor that is being assembled on the new line is Renault’s new ePT-160kW. Developed through a joint effort of the Renault-Nissan-Mitsubishi Alliance, the motor produces 160 kilowatts of power and 300 newton-meters of torque. It will equip all of Renault’s battery electric models, including the Megane E-Tech Electric, which is assembled at the carmaker’s plant in Douai, France, within the ElectriCity cluster.

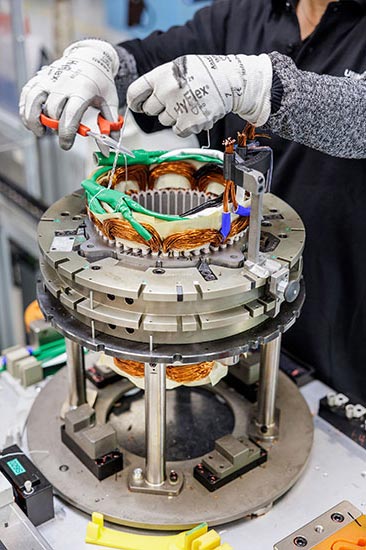

The ePT-160kW is a synchronous motor with a wound rotor, a technology that Renault Group has been using for 11 years and which offers better efficiency than a permanent magnet motor. In addition, the absence of rare earths ensures a secure supply of raw materials and limits the motor’s environmental impact and production costs. More compact and lighter than the Zoe’s electric motor, it has more power and better torque. It offers all the benefits of electric driving, including instant acceleration that is both dynamic and linear.

The ePT-160kW is a synchronous motor with a wound rotor, which offers better efficiency than a permanent magnet motor. The motor does not use rare earth elements, which limits the motor’s environmental impact and production costs. Photo courtesy Renault Group

A Change in Direction

Opened in 1958, the Cléon plant produces gas-powered engines, electric motors, gearboxes and aluminum castings for the Renault range. It also supplies components to Alliance members Dacia, Renault Samsung Motors and Nissan, as well as automotive OEMs Fiat and Daimler. In 2022, the factory produced 276,003 gas-powered engines, 317,343 electric motors, 199,555 gearboxes and 13,163 tons of aluminum castings.

The plant has a history of deploying Industry 4.0 technologies. In 2020, for example, the facility installed three fully automated machining lines to produce crankshafts, cylinder housings and cylinder heads. Sensors in the connected machines automatically send alerts to maintenance technicians when, for example, they detect an unusual rise in temperature or abnormal vibration on a bearing.

Renault’s ambition is to phase out production of gas-powered passenger vehicles for Europe and produce nothing but electric passenger vehicles by 2030. Photo courtesy Renault Group

The plant also employs automated guided vehicles, 3D printing, exoskeletons, collaborative robots and virtual reality training. Digital applications on smartphones make everyday life easier for operators.

Renault’s pivot to EV manufacturing was initiated in 2012, and the company plans to locate as much of its EV value chain in France as possible. Renault’s ambition is to phase out production of gas-powered passenger vehicles for Europe and produce nothing but electric passenger vehicles by 2030.

“An emblematic site at the heart of the Renault Group’s industrial ecosystem, the Cléon plant is the largest production center for electric motors in France,” says Jose Vicente de los Mozos, Renault’s industrial director. “[We are at] a new stage in our conversion to electric power, and it is a great source of pride for [our] employees to produce this new electric motor for the Renault Mégane E-Tech. Cléon is the perfect example of the group’s industrial transformation towards the electric vehicle and its entire value chain, involving our employees, our social partners and our local stakeholders.

“Another future electric motor, developed jointly with Valéo, will also be assembled here and will reinforce the Renault Group’s commitment to the Cléon plant and its desire to base its activities in France.”

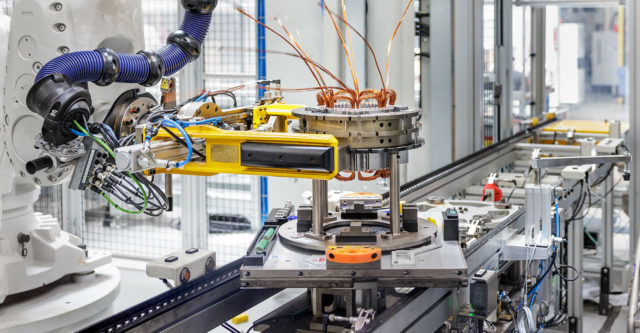

Half the Cléon factory’s output will go to battery electric vehicles, while the other half will be installed in hybrid vehicles. Photo courtesy Renault Group

A Factory Geared Towards EVs

Prior to the addition of the new assembly line, the Cléon plant was equipped with four assembly lines and two winding lines with a production capacity of 240,000 motors per year.

Since 2015, the Cléon plant has been producing the electric powertrain for Renault Zoé, Twingo ZE, Kangoo ZE and Master ZE. Now, it is expanding its range with the mass production of the ePT-160kW motor, which will also equip a future Renault C-segment model. Beginning in 2024, production will be expanded with the ePT-100kW motor for the future Renault 5 electric car. Later, beginning in 2027, the line will produce a next-generation 200-kilowatt motor, designed without rare earths and developed in partnership with Valeo and Valeo Siemens eAutomotive.

To train workers for the transition to EV production, an onsite training facility, the E-Mobility Academy, has been established at the Cléon assembly plant. Photo courtesy Renault Group

To support this large-scale transition to EV production, Renault is training employees in new manufacturing disciplines. For example, at the Cléon assembly plant, Renault has established a unique onsite training facility, the E-Mobility Academy. The academy and curriculum were developed with the help of several partner organizations, including Renault Trucks; the National Conservatory of Arts and Crafts, the French equivalent of an Ivy League university dedicated to science and industry; and Engineers 2000, a nonprofit organization established by Renault, Schneider Electric and several other French manufacturers to develop apprenticeship programs.

Renault’s Cléon Assembly Plant by the Numbers

Renault has invested $664 million in the Cléon factory since 2018 to automate assembly of electric motors and other EV components. Photo courtesy Renault Group

- 98 million engines and gearboxes produced since the plant opened in 1958.

- $664 million invested since 2018 to automate assembly of electric motors and other EV components.

- In 2021, the site produced 934,459 mechanical components, 34 percent of which were for EVs.

- As of December 2022, the plant employs 3,195 people, of which 14 percent are female operators and technicians and 7 percent are female managers.

- The facility occupies 155 hectares of space, of which 40 hectares are buildings.

- Certifications include ISO 9001, ISO 14001 and ISO 50001.

Watch our behind-the-scenes look at the new line

ASSEMBLY ONLINE

For more information on Renault’s manufacturing operations, read these articles:

Renault Retrofits Robots at Refactory

From ICE to EV: Factory Conversion Helps Renault Go Electric

Heavy-Duty Electric Trucks