Applicators, crimping machines and other types of high-voltage cable and wire processing equipment play key roles in electric vehicle production. They’re the unsung tools that enable automakers and suppliers to increase throughput and minimize waste.

Application tooling encompasses the equipment and services used for electrical connection applications such as crimping a terminal onto a wire or pressing a connector onto a board. When used correctly, application tooling maximizes production uptime and increases productivity.

Demand for high-voltage connectors and wire harnesses is increasing as electric vehicles become more popular. The global connector market is expected to more than double this decade, reaching $178 billion by 2032, while the worldwide wire harness market is projected to reach $58 billion by 2030.

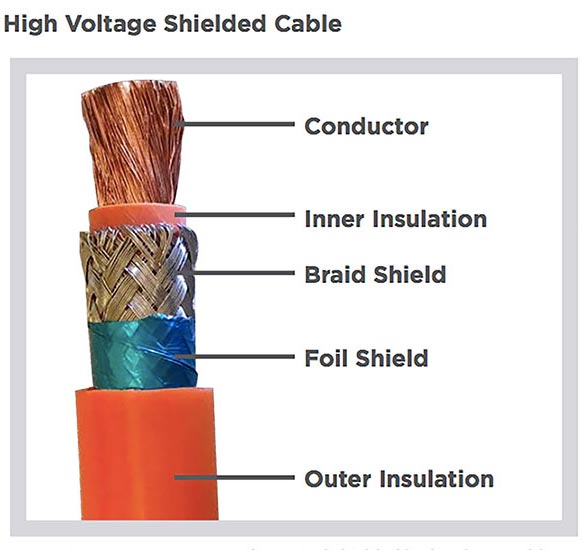

Large wire applications involving cables larger than 10 millimeters in diameter are now used widely throughout the automotive industry. Illustration courtesy TE Connectivity

Large wire applications involving cables bigger than 10 millimeters in diameter are now used widely throughout the automotive industry to connect battery modules and EV architectures. Automakers and suppliers are looking for advanced crimping tools to prepare and terminate aluminum- and copper-stranded high-voltage cables.

However, this is no easy matter. Assemblers have to avoid “footballing” wire, damaging insulation, removing foil shields incorrectly and making other costly errors.

Fast-paced industry developments are forcing application tooling vendors to continually update their products. The tools used tomorrow to assemble fully autonomous vehicles will look much different than the tools used today to prepare and crimp wires for EVs equipped with advanced driver assistance systems.

Wiring harness professionals should prepare for constant change by adopting a mindset of continuous learning and getting certified on new solutions. For manufacturers, however, the rate of change and the current focus on cost controls is complicating efforts to offset automation investments.

Does Automation Make Sense?

Many automakers and suppliers are preparing for the future by adopting new technologies. But, engineers must consider whether automation makes sense for each wire processing application.

Many EV manufacturers are startups and just beginning to ramp up production. For firms like this, automation doesn’t make sense. Companies choose to automate tools when they scale production and need greater business efficiencies. For other applications, they will just wait for the market to catch up.

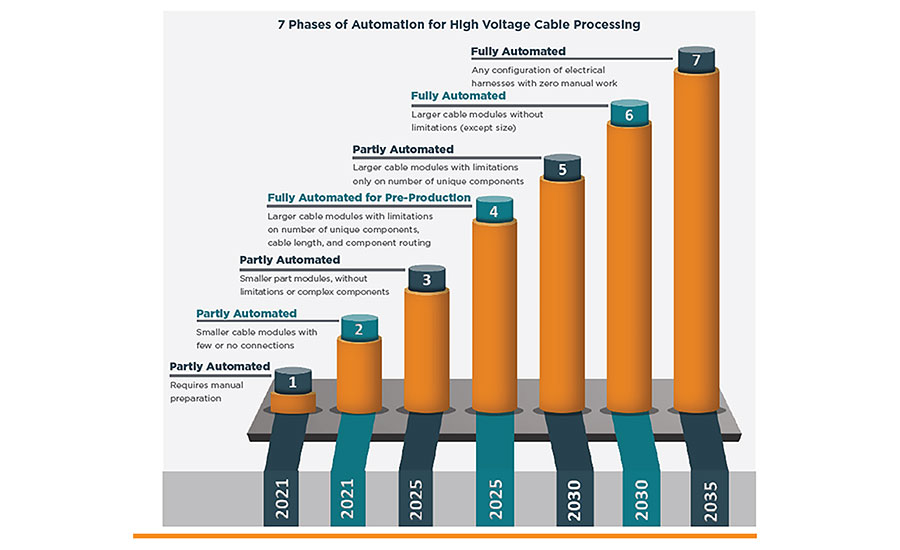

Currently, only smaller cable or part modules that are simply designed can be easily automated. However, by 2035, high-voltage cable processing will likely be fully automated, enabling more companies to streamline their operations.

High-voltage wire harnesses are designed to fit applications with as little extra cabling as possible to help reduce weight. Cutting off a bad crimp can ruin an entire harness assembly, costing a firm thousands of dollars in wasted products and production hours.

If employees are creating more errors, due to excessive production demands, the value proposition for automating some processes begins to look more attractive. Similarly, labor constraints and increased competition for top talent may push some firms to automate sooner than others.

Manufacturers want to deploy multipurpose machines that automate more processes, providing higher return on investment.

Ultrasonic welding machines, for instance, can automatically process different cable materials, such as aluminum and copper, as well as handle different diameters, up to 20 millimeters, providing more value-added benefits.

Application tooling is highly customized to individual companies’ needs. So, EV manufacturers should seek partners that are willing to co-develop solutions, perform value engineering to control costs, evolve functionality in response to field feedback, and be highly responsive when it comes to troubleshooting and maintaining equipment.

There are seven phases of automation for high-voltage cable processing. Illustration courtesy TE Connectivity

AI Will Transform Application Tooling

In the near future, application tooling will use artificial intelligence technology to validate processing steps, track products through multistep assembly lines and communicate with manufacturing execution systems to improve efficiency.

While human operators can perform visual inspections to identify many errors with terminal, die or wire placement, AI can eliminate potential errors before they happen. To improve accuracy and repeatability, AI systems use cameras and sensors that are added to a high-force press, electronically validating accuracy and improving traceability.

For example, current advanced high-voltage cable processing systems use multiple cameras and AI to scan crimper, anvil, wire and terminal to confirm compatibility. They then analyze multiple parameters that have been preloaded into the machine software and use that data to determine the current crimp profile. Then, the system measures the placement and angles of the terminal to confirm that everything is set and in proper alignment.

In the next few years, we’ll see more manufacturers fully automate assembly lines, using advanced AI to maintain product accuracy as cables travel from process to process and machine to machine.

Robust traceability systems will track products throughout the process, confirming that the appropriate equipment, such as the die set, was used and that important metrics were maintained, such as wire alignment, crimp height and termination speed.

These systems will be able to perform advanced checks, such as validating that wires are correctly positioned, ensuring that the correct terminal is being used for the installed die set and is placed properly on the wire and seated accurately in the lower die nest. They will also perform cable checks, validating that the outer diameter, centerline, protrusion, insulation in terminal and strip length, are all accurate.

Constant innovation will define the future of EV production. Manufacturers that thrive will use digital systems and data analytics to optimize designs and manufacturing processes.

By choosing the right applicator tooling and automating to scale production, automakers and suppliers can increase throughput and ensure high quality subassemblies.