New Process Welds Clear Plastic Parts

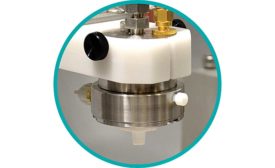

Clear polymer materials can be successfully bonded with a new process that combines simultaneous through-transmission infrared laser welding with precision ultrasonic spray deposition technology

Read More