Home » Keywords: » pick-and-place machine

Items Tagged with 'pick-and-place machine'

ARTICLES

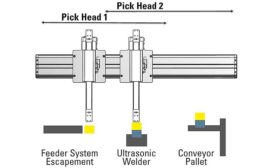

Motion Control: Rigid vs. Flexible

"If production volume is high, that points to rigid automation."—Chris Knudsen, Yaskawa America Inc.

July 1, 2013

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing