Home » Keywords: » force-distance monitoring

Items Tagged with 'force-distance monitoring'

ARTICLES

Engineers can do more with force and torque data than simply make “good” or “not good” decisions about assemblies

Read More

advertisement

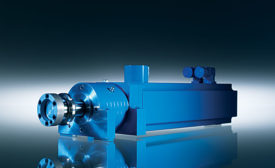

How To Select the Right Electromechanical Servo Press for Your Assembly Operation

March 8, 2016

advertisement

How To Determine the appropriate press technology for high-force, high-speed applications.

March 7, 2016

Automotive Applications for Assembly Presses

There are myriad applications for assembly presses in the automotive industry.

May 1, 2014

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing