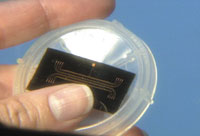

Companies such as Bookham Technology (Abingdon, Oxfordshire, UK), Digital Optics Corp. (Charlotte, NC), Lightwave Microsystems Corp. (San Jose, CA) and Nanovation Technologies Inc. (Miami) have developed processes to manufacture components based on silicon chips. By using this technology, the companies take advantage of standard, high-volume semiconductor assembly processes that offer much higher yields.

"While traditional fiber optic component manufacturers combine discrete elements, such as lasers, lenses and filters, in manually assembled devices, we can achieve the same functionality in a single integrated silicon chip," says Andy Cornish, vice president of manufacturing at Bookham Technology. Cornish boasts that this process significantly reduces the cost, time and complexity of assembling fiber optic components.

Scalable, high-volume production permits a wide variety of optical components to be manufactured using established process steps developed by the semiconductor industry. "Conventional optical devices require considerable skill and manual manipulation to attach and align optical fibers," Cornish points out. "Our technology allows for a much simpler fiber attachment, resulting in easier and quicker device packaging and interfacing."