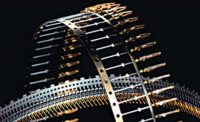

Semiconductor device fabrication is a complex, multistep process involving both photolithographic and chemical techniques. Step one involves slicing an ingot of semiconductor material, typically monocrystalline silicon, into thin wafers. Each wafer then undergoes a microfabrication process and serves as the substrate for hundreds of integrated circuits (IC) that get cut into individual chips.

To obtain the highest quality chips, the silicon ingot must be free of all defects. This is critical, because the wafer undergoes stress during slicing, fabrication and cutting. Cracks at any stage of production make the wafer unusable.

Many IC manufacturers in Asia use infrared imaging microscopes to verify that semiconductor material is defect-free before slicing, and that circuits are crack-free afterward. Singapore-based Radiant Optronics Pte Ltd. builds this type of microscope and incorporates the short-wave infrared (SWIR) Goldeye G-008 camera made by Allied Vision Technologies Inc. Christopher Cheong, director of Radiant Optronics, likes the G-008 because it is compact, robust, economical and suitable for applications that don’t require high-resolution-image detection of material defects.

The camera’s main feature is an indium gallium arsenide sensor that detects wavelengths of 900 to 1,700 nanometers. This range bridges near-infrared (700 to 1,400 nanometers) light and SWIR (1,400 to 3,000 nanometers) light. Visible light is in the 400 to 700 nanometer range.

The G-008 is capable of rates up to 344 frames per second, at a full resolution of 320 by 240 pixels. It operates in temperatures from -20 to 55 C, although a thermo-electric cooling device ensures color-consistent images regardless of ambient temperature.

Also standard are a GigE Vision interface that includes Power over Ethernet, and I/O controls that synchronize with various types of software and assembly systems. C-, F- and M42 mounts are available and allow for easy integration.

Manufacturers use the G-008 for a wide range of inspection work. Plastics recyclers, for example, use it to sort materials. The camera enables medical companies to perform hyperspectral imaging, microscopy and optical coherence tomography, and manufacturers in the metal and glass industry use the camera to take thermal images of objects up 800 C.

Other common uses include airborne inspection of agricultural fields, banknote inspection and laser profiling of electronics. Surveillance and security companies rely on the camera for vision enhancement through fog or at night.

Radiant Optronics specializes in optoelectronic technology. Radiant has offices in Malaysia, Shanghai, Taiwan and Thailand, but is headquartered in Singapore. Its customers include companies involved in semiconductors, biotechnology, packaging and PCB

assembly, as well as research and development laboratories.

Allied Vision’s Goldeye series is part of its Extreme industrial-grade camera family, along with the Prosilica GT and Bonito PRO. The supplier’s Essential line includes Mako and Guppy PRO cameras. Manta and Stingray cameras comprise the Enhanced line.

All cameras are assembled in facilities that are ISO 9001 certified and comply with the ISO 13485 quality standard for medical devices. For more information on short-wave infrared and other cameras, call 877-872-1394 or visit www.alliedvision.com.