Component uniformity and product quality often go hand in hand. Knowing this, manufacturers do all they can to find the right equipment that ensures such uniformity batch after batch, day after day.

For harness manufacturers, the equipment best suited for this task is the fully automated cut, strip and crimp (CSC) machine. This type of machine also offers high speed, efficiency and reliability.

“Nine out of 10 companies that use an automated cut, strip and terminate machine do so primarily because they need high-volume wire processing,” notes Rob Boyd, senior product manager at Schleuniger Inc. “Manufacturers with high-mix, low-volume production like it for its quick changeover capability. Some companies do purchase and use the fully automated machine strictly because of its reliability, but that’s rare.”

Processing speed is one of the main reasons why Lake Worth, FL-based Benchmark Games International purchased a Schleuniger CrimpCenter 36 S CSC machine in 2018. From 1993 to that point, the redemption-games manufacturer either outsourced its wire processing or had in-house workers do it manually.

However, an analysis of its manufacturing process determined the primary cause of failures to be incorrect wiring, and damaged pins and connectors. This realization, along with the need to have workers spend less time on mundane wiring tasks, convinced the company to automate its wire processing.

With the CrimpCenter 36 S, Benchmark has increased production, and cut its labor hours and wire-related failures by 50 percent. Typical CSC machine tasks include cutting wire to length, stripping both ends, applying the pins and performing pull-force testing as identified by the pre-setup program.

“A single operator can produce thousands of completed wires each day,” says Jeff DeLong, quality assurance director at Benchmark. “Complete wire packages are then delivered to the wire-board assembly area, allowing us to entirely skip any manual testing and crimping.”

DeLong notes that Benchmark’s high production rate enables the company to process wire the day before assembly, rather than producing and storing it for weeks at a time, which can result in damage from storage and handling. He also likes the CrimpCenter 36 S’s automated and controlled quality testing, which saves the company time and money, and enhances its reputation for quality products.

Like many other harness manufacturers, Benchmark is better able to meet its customers’ wire processing needs because of CSC technology. The many benefits and capabilities these machines offer on a daily basis provide end-users a positive experience in the plant and a competitive advantage in the marketplace.

Yesterday and Today

Some assembly technologies constantly evolve, while others change in spurts. CSC machines belong in the latter category.

“For many years, all wire processing actions in CSC machines were done mechanically or pneumatically,” notes Boyd. “Some time later, stepper motors began to be used. Now, advanced servo technology is commonplace. On today’s CSC machines, about 80 percent of processing actions are computer based.”

Artos Engineering Co. developed the first CSC machine in the early 1930s for the Western Telegraph Co. to help it more quickly process wire for the radios it manufactured. This machine featured three pairs of fixed-position blades to cut and strip the wire. All setup changes were done mechanically by adjusting cams and moving blade spacers, and the machine automatically placed terminals at the end of each wire.

In 1976, Switzerland-based Komax AG introduced its first wire cutting machine with a stepper-motor drive. Just five years later, the company brought its Komax 40 CSC model to market in Europe. This machine pushed wire, rather than pulled it, and allowed operators to program various processing parameters, like wire length and cycle speed.

Schleuniger developed its CrimpCenter platform in 2002, before introducing its CrimpCenter 64 machine in 2004 and the CrimpCenter 36 in 2009. Boyd notes that the 6 series was initially made for high-end auto harness makers, and the 3 series for non-automotive industries. Now, both series are equally used by each group.

Regardless of supplier, today’s CSC machines handle a wider range of wire (30 to 10 AWG, depending on series) than earlier models and use servomotors for all wire movements to increase processing speed and precision. The machines also feature advanced HMIs, which allow operators to quickly change wire parameters and processing speed, access real-time crimp force monitoring data, and easily integrate the CSC with other assembly machines via plant management software.

Another advantage of modern CSC machines is they allow faster and simpler changeover. This is due mainly to quick-change guides and process-specific technologies. The Sencor system from Artos, for example, senses the conductor within the wire and automatically sets blades at the proper stripping diameter, resulting in less wire waste and shorter setup times. Schleuniger has a ToolingShuttle system that lets operators change out the CSC’s crimp applicator in 30 to 40 seconds, rather than 5 or 6 minutes.

Hard at Work

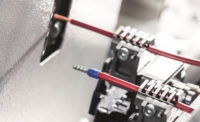

CSC machines are standalone models that feature a blade block that contains one set of cutting blades and two sets of stripping blades (one for each end of the wire). Blade types are V, rotary, radius and custom die. Occasionally, such as when the wire requires a long strip length, cutting blades are also used for stripping.

CSC machines process the ends of one or more different wires simultaneously (i.e., the trailing end of wire A and leading end of wire B) to optimize productivity. After a wire is cut and stripped, it is automatically placed into a terminal that is crimped with a press. The finished wire is then deposited into a collection tray for retrieval. Cycle time is 0.5 to 2 seconds.

A wide range of secondary process stations may be integrated with CSC machines. These operations may be performed either before or after crimping and include fluxing, tinning or soldering wire; placing an insulating sleeve over one or more wire; machine vision; retrimming wire; and marking (laser, ink-jet, hot-stamp) or welding (ultrasonic, resistance) wire.

Other stations may install a weather seal to the connector or twist two wires together and insert them into a single terminal. Manufacturers of electrical control cabinets often integrate their CSC machines with a welding station, which compacts exposed conductor strands into a slug that is then inserted into a terminal block.

Since 2018, makers of harnesses for many industries have used the Artos CrX-44HD machine to cut, strip and crimp copper and aluminum wire from 10 AWG up to 00 AWG, and cut and strip cable up to 000 AWG. The machine’s powerful processor features a heavy-duty feed drive, cutter head, wire straightener and pneumatic grippers. Maximum crimping force is 150 kilonewtons.

Joe Peterson, director of technical services at Artos, says the machine features robotics-based pick and place technology that properly positions loose-piece closed- and open-barrel terminals for termination. Another key feature is durable tooling, which enables fast changeovers of the terminal and die set, and lowers replacement costs due to extended wear life. Processing options on the machine are solder pots, heat shrink sleeve insertion and welding.

Both the Omega 670 and 750 linear-drive machines from Komax come with a sensor-based, lock-loading feature that precisely inserts large or small wire directly into the connector, eliminating the chance of improper insertion. These machines can be used with up to 13 process stations, according to Erich Moeri, inside technology engineering manager at Komax.

An automatic wire changer lets operators simultaneously process up to 36 different 26 to 14 AWG wire. Process parameters are directly sent to the machines via a network, and all production data is saved for full traceability of each processed wire.

Another key feature is automatic conductor detection technology, which detects the slightest contact between any standard blade and conductor strands during stripping. Defective wire ends are immediately detected and rejected.

Up to the Challenges

There are a number of challenges to using CSC equipment, but the latest technology has been designed to overcome these issues. One challenge is ever-changing wire and insulation materials. Peterson gives the example of halogen-free insulation becoming more standard to eliminate the risk of fire. Such insulation is harder and tougher than traditional materials.

“Wire is always getting smaller, partly due to product miniaturization and partly because automobiles increasingly require smaller-footprint harnesses,” adds Peterson. “Harness manufacturers are also processing more aluminum wire, particularly for companies that make solar panels. This wire can have insulation up to 5 millimeters thick, which isn’t the easiest to cut.”

Worker turnover remains a problem as well, according to Moeri. As a result, companies are often left without experienced, trained people who know how to optimize the performance of each CSC machine.

“This loss frequently happens without the transfer of equipment knowledge to the incoming operators, resulting in the need to fully train them,” says Moeri. “One step we’ve taken, as a machine supplier, is to now offer what we call online training modules for each of our machines. This complements the initial onsite training we provide operators, because workers can consult them as they need to. This online training also counts towards worker certification.”

Boyd says it’s very important that operators only use terminals that work properly with their machines. Failure to do so can lead to poor crimps and system downtime. The same is true for the crimping applicator, which feeds the terminal, cuts it from the strip, and crimps it onto the wire.

“Overcoming wire memory is an ongoing challenge as well,” notes Boyd. “The best way to ensure straight wire is to not buy it on little spools. It’s always best to go with barreled wire whenever possible. But, if you do buy spooled wire, we recommend the spool have a core of at least 8 inches in diameter.”

Dereelers and prefeeders keep wire straight as it is fed from the spool into automatic CSC equipment, but they do it in slightly different ways. Dereelers push the wire into processing equipment, whereas prefeeders pull the wire.

Positioned either right after the spool payoff or at the beginning of an automated wire processing line, these devices also prevent tangling and eliminate delivery drag. Both actions can create inconsistent wire lengths.

Machine maintenance is equally important, and should be performed daily, weekly or monthly, depending on level of production. Some suppliers offer each customer a maintenance agreement, whereby the supplier’s tech specialists perform the more complex maintenance tasks related to wear components on a biannual or annual basis.

On the positive side, notes Peterson, most CSC machines are technologically advanced enough to allow plant managers to remotely monitor the units and perform troubleshooting. Moeri concurs, adding that today’s equipment is also easier to program and automatically performs data digitization.

“The operating software and built-in interfaces have advanced to the point where a line manager can instantly check machine status on a cell phone,” notes Moeri. “Programming has never been simpler for operators, in terms of changing processing and sorting parameters.”

Easier networking of CSC machines is another beneficial capability. The main reason, according to Boyd, is it enhances traceability for quality checks, such as crimp height measurement and pull testing. An extra benefit is higher quality wire due to the elimination of cutting, stripping and crimping errors.

Schleuniger’s CrimpCenter 36 SP and CrimpCenter 64 SP CSC machines offer high-precision technology. The CrimpCenter 36 SP enables quick setup, thanks to wire straighteners and programmable gripper pressure. This machine also features refined motor synchronization, an automatic batch tray and a deposit gripper for higher feed rates.

The CrimpCenter 64 SP has a dynamic and powerful control system that ensures high production rates. It allows up to four processing stations, whereas the 36 SP allows up to six. Both machines handle wire from 26 to 10 AWG.