The EV Lightweighting Challenge

Lightweighting efforts focus on new materials to improve operating range.

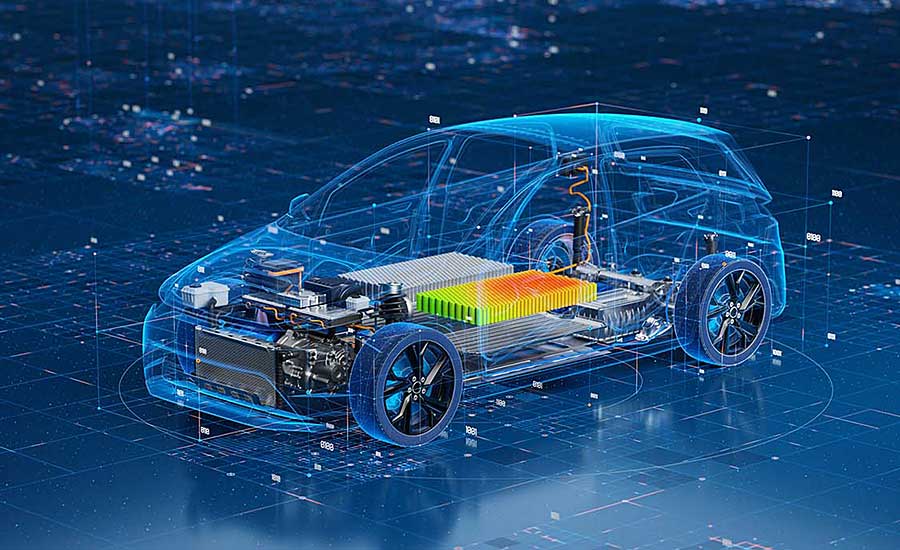

Lightweighting can improve the strength, stability and performance of electric vehicles. Illustration courtesy Altair Engineering Inc.

Steel remains a popular material, because it is versatile and uses conventional high-volume assembly processes, such as riveting and welding. Illustration courtesy Steel E-Motive

The unique properties of high-strength steel can be tailored to solve complex design challenges, while achieving strength and safety requirements. Illustration courtesy Steel E-Motive

Advanced materials research is leading to lighter weight batteries and EV components. Photo courtesy University of Warwick

This lightweight battery enclosure improves thermal management and reduces assembly complexity. Photo courtesy Kautex Textron GmbH & Co. KG

Aluminum can reduce the weight of battery enclosures, while improving strength and stiffness. Photo courtesy Alumobility

An innovative timber joining process developed in England is based on friction welding technology. Photo courtesy TWI

These lightweight crash-critical stampings are made from aluminum. Photo courtesy Fischer Group GmbH

Lightweighting can improve the strength, stability and performance of electric vehicles. To address the challenge, automakers are exploring new materials that boost operating range, one of the biggest hurdles to widespread EV acceptance.

Battery technology has played its part and continues to do so with advances in materials to get the most mileage from a single charge. However, better batteries are typically heavier, which means mass has to be cut elsewhere in EVs.

Electric vehicles tend to be much heavier than their gas-powered counterparts. For instance, the Ford F-150 Lightning weighs up to 3,000 pounds more than the traditional version of the popular pickup truck. And, the battery pack alone of the GMC Hummer EV weighs about the same as a Honda Civic.

Engineers are scrambling to find cost-effective alternatives. For instance, when developing the new RS1 sport utility vehicle, Rivian opted to go with a combination of aluminum, carbon-fiber composite and high-strength steel structural components.

Even in the EV age, good old steel remains a popular material, because it is versatile and uses conventional high-volume assembly processes, such as riveting and welding. Its unique properties can also be tailored to solve complex design challenges, while achieving strength and safety requirements.

One of the most interesting recent developments is Steel E-Motive, a collaboration between Ricardo and WorldAutoSteel. The goal of the R&D project is to create a lightweight autonomous vehicle platform.

WorldAutoSteel comprises 20 of the largest automotive sheet metal producers in the world, including Arcelor Mittal, Nucor and U.S. Steel. Ricardo serves as the organization’s engineering partner.

Designs of SEM-1 and SEM-2—the fully autonomous mobility-as-a-service vehicles at the heart of Steel E-Motive—recently emerged, and development work continues. Specific details are being kept under wraps, but engineers hope to achieve a driving range of 250 to 300 miles. That’s enough to operate in a city for an entire day without the need to recharge batteries.

“It’s a clean sheet vehicle, with different requirements and specifications than anything we’ve done before,” says Neil McGregor, chief engineer for systems integration at Ricardo. “Therefore, we spent time getting the primary layout of the vehicle right. Obviously, with Level 5 autonomy you have no steering wheel, pedals or driver control. So, when you take those out of the engineering equation, it gives you a lot of freedom.

“The characteristics of steel really help us in engineering,” explains McGregor. “The high strength, high ductility characteristics were essential to getting the end product. Over the course of development, we’ve actually amassed a product portfolio of over 60 different advanced high-strength steel grades that are available.”

More steel developments have come courtesy of a similar partnership between Tata Steel and the University of Warwick. The duo are developing environmentally friendly steel grades, coatings, films and battery structures. The long-term goal is to make steel cleaner, greener and more responsive to the fast-changing needs of customers across a variety of sectors.

Engineers at the WMG International Manufacturing Centre at the University of Warwick are focusing on advanced materials, lightweighting, electrified propulsion systems, digital manufacturing and circular supply chains.

“WMG has worked with Tata Steel on projects for many years, and this partnership will see the collaboration grow across key research themes, including decarbonizing the supply chain and enabling future applications of steel across zero carbon propulsion systems and transport vehicles,” explains David Greenwood, professor of advanced propulsion systems and CEO of the High Value Manufacturing Catapult at WMG. “This activity will include identifying new collaborative relationships and developing world-class technology for the future of the steel industry.”

Lightweight EV Traction Motors

Engineers at India’s Vellore Institute of Technology and Poland’s West Pomeranian University of Technology are focusing on creating electric traction motors with lightweight materials. Their efforts are based around the fact that EVs currently use different cooling systems for electric motors. For instance, water-cooled systems are widely employed instead of conventional fan-cooling systems, which are both bulky and heavy.

The water-cooled approach keeps electric motors cool and at peak efficiency without sacrificing vehicle weight and performance. However, they also have a number of issues, such as leakage, which reduces overall efficiency. And, the motors require extra equipment to run, such as pumps, pipes and radiators. This makes them more difficult to maintain than conventional fan-cooled systems.

To overcome weight issues and maintain optimal efficiency in electric motors, research has focused on the use of advanced materials in components such as water-cooling systems. Studies have investigated many different materials in recent years, including carbon fiber and polymer-based composites. Improving the design of components and evaluating the use of advanced materials in electric motors overcomes many of the issues with current technologies.

One of the major components of an induction motor is the start coil. These are usually constructed from metallic materials such as aluminum, copper and silicon steel. Changing the material used in the outer casing, for example, and using fiber-reinforced polymers instead reduces the weight of these components and improves the overall efficiency of motors.

The European engineers explored different possibilities for reducing the weight of electric motors using various lightweight materials without sacrificing overall power efficiency and performance. Specifically, they focused on a fluid-cooled motor.

Thermal analysis demonstrated the increased efficiency of using an axial housing water jacket to provide cooling compared to the conventional, completely enclosed fan-cooled motor.

In addition, finite element method (FEM) analysis was carried out to look at differences in temperature ranges and gradients. The water-cooled motor possessed a lower temperature range than its fan-cooled counterpart.

PA6GF30, a glass fiber-reinforced polymer composite, was also evaluated. The ability of this material to reduce the highest temperature of the system was nearly comparable to aluminum, which is traditionally used for this purpose.

Pack to the Future

Battery enclosures are one of the least glamorous, but most important components of EVs. They’re also big and bulky. However, aluminum and carbon-fiber composites can be used to reduce weight, while improving strength and stiffness.

At last month’s Consumer Electronics Show in Las Vegas, Kautex Textron GmbH & Co. KG displayed the latest version of its Pentatonic battery system, which is produced from thermoplastic or composite metal hybrid.

The system offers automakers several advantages vs. steel and aluminum alternatives, including improved thermal management and insulation, resistance to corrosion, up to 40 percent reduction in CO2 footprint and up to 60 percent reduction in weight.

In addition, a “one-shot production process” uses reinforced materials and integrates structural elements directly into the injection or compression molding process. That simplifies assembly and decreases complexity by eliminating the need for welding.

“Pentatonic is designed to help OEMs reduce the overall system weight and simplify their production process,” says Richard Brooks, vice president of sales at Kautex. “Features and thermal management components like cooling plates are integrated into one fully capable, lightweight system.

“Reduction of secondary process steps simplifies assembly, reducing customer bill of material and improving cost up to 20 percent,” adds Brooks. “Fewer assembly steps reduce the number of sealing joints, which lessens the risk of leakages.”

In Spain, engineers at the Technological Institute of Plastics (AIMPLAS) recently developed a lightweight battery case for EVs as part of the SMART5G project. The new enclosure swaps metal for plastic.

The recyclable, long-fiber thermoplastic composite uses flame-retardant additives and particles for electromagnetic shielding. AIMPLAS claims the component will increase vehicle range, thereby cutting energy costs and consumption.

“Thermoplastic matrix composites [offer] many advantages, including weight reduction, high rigidity and specific strength comparable to metal materials,” says Begoña Galindo, Ph.D., a sustainable mobility researcher at AIMPLAS. “The new generation of EV manufacturers is starting to use these plastic materials, which enable free design and make cars around 40 percent lighter.”

Meanwhile, engineers at Chalmers University of Technology in Sweden have created a carbon fiber structural battery that performs 10 times better than previous generations. The material in the battery acts as an electrode, conductor and load-bearing material at the same time and could lead to massless batteries in the future.

The battery has an energy density of 24 watt-hours per kilogram (Wh/kg), meaning approximately 20 percent capacity compared to comparable lithium-ion batteries currently available. However, since the weight of vehicles can be greatly reduced, less energy will be required to drive an electric car and lower energy density also results in increased safety. And, with a stiffness of 25 gigapascals (GPa), the structural battery can compete with many other commonly used construction materials.

“Previous attempts to make structural batteries have resulted in cells with either good mechanical properties, or good electrical properties,” notes Leif Asp, Ph.D., a materials science professor at Chalmers University of Technology. “But, using carbon fiber, we have succeeded in designing a battery with both competitive energy storage capacity and rigidity.”

According to Asp, the new battery has a negative electrode made of carbon fiber and a positive electrode made of a lithium iron phosphate-coated aluminum foil. They are separated by a fiberglass fabric in an electrolyte matrix.

A new project, funded by the Swedish National Space Agency, is currently underway, where the performance of the structural battery will be increased further. The aluminum foil will be replaced with carbon fiber as a load-bearing material in the positive electrode, providing both increased stiffness and energy density. The fiberglass separator will be replaced with an ultra-thin variant, which will give a much greater effect, as well as faster charging cycles.

Asp estimates that such a battery could reach an energy density of 75 Wh/kg and a stiffness of 75 GPa. This would make it about as strong as aluminum, but with a much lower weight.

Wood You Believe It?

One material that was widely used in vehicle structures many decades ago could make a surprising comeback in the future. Engineers at TWI have been working with a group of British universities, including Cambridge, to harness new uses for wood. They’ve developed an innovative timber joining process that is based on friction welding technology.

The process produces fused timber joints that are stronger than conventional glues, and even stronger than the native wood. In contrast with traditional methods, such as adhesives, this method can reliably produce high quality bonds without the need for any mechanical fasteners, binders or a curing process. It is compatible with a wide range of woods, including lightweight variants such as bamboo laminate and slash pine.

Believe it or not, timber also holds promise for battery manufacturing. Trees are composed of 20 percent to 30 percent lignin, where acts as a binder and gives wood its stiffness and resistance to rotting. Lignin is a plant-derived polymer found in the cell walls of dry-land plants. Being a side stream in the production of cellulose fiber, it is one of the biggest renewable sources of carbon anywhere.

One of the challenges of lithium-ion batteries is the use of graphite. The nonrenewable carbon must be either mined or made from fossil-based materials.

To address the issue, Stora Enso, a Swedish forest products company, and Beyonder, a Norwegian battery manufacturer, have developed a renewable way to process lignin into an anode material for batteries. Stora Enso, which is producing bio-based carbon materials at a plant in Sunila, Finland, is also working with Northvolt on a similar project. It hopes to “develop the world’s first industrialized battery featuring anode-sourced entirely from European raw materials, lowering both carbon footprint and cost.”

Aluminum Reduces EV Weight

Aluminum is another lightweight material that is increasingly being used in EVs produced by both legacy manufacturers and startups. For example, Lucid Motors is using aluminum for things such as door rings, B-pillars and battery pack covers.

The hot-formed components used in the Lucid Air sedan were designed and manufactured in collaboration with AP&T North America Inc. and Fischer Group GmbH.

“AP&T presented a promising new technology,” says Eric Bach, senior vice president of product and chief engineer at Lucid. “The potential benefits were significant, because hot-forming enabled the manufacturing of complex part geometries with high-strength aluminum.

“Thanks to the combination of high formability, high strength and low weight, the design of the components could truly be optimized,” claims Bach. “This allowed the utility package space to be used more efficiently and to achieve a high level of collision safety and low energy consumption.”

The collaborative engineering process began more than seven years ago, when Lucid engineers reached out to AP&T with a variety of part and process requirements. During 2017, the development work accelerated, with the use of computer-aided engineering analysis. AP&T's forming experts executed FEM sheet metal simulations, which predict possible risks of cracks and wrinkling that could occur during the forming process.

That same year, AP&T presented the first full-scale production line for hot forming high-strength aluminum to demonstrate the potential of the new technology. The innovation received the Altair Enlighten Award.

Numerous trials of different aluminum alloys from various suppliers were conducted at AP&T's test line in Ulricehamn, Sweden. The team implemented parameters recommended by these material suppliers into the production process.

It was during this project phase that the optimal material, stamping process and heat treatment parameters were defined. The process robustness was validated through an intensive experimental study that included material testing at the suppliers' test laboratories and significant component testing by Lucid engineers.

After the best performing materials were selected, prototype dies were provided by AP&T. Prototype parts were stamped on its production line to build Lucid’s beta prototype and release candidate cars, which were subjected to rigorous component and vehicular-level testing.

“Thanks to the usage of FEM sheet metal forming simulation models, production capabilities were enabled in a really short time frame,” says Michael Machhammer, Ph.D., manager of development forming processes and tooling at AP&T. “It was possible to shorten the tool try out time tremendously by using the simulation models which had been optimized in a number of research projects.”

Based on past successes and a long working relationship, AP&T recommended the Fischer Group as the manufacturing partner to help meet Lucid’s quality demands. Production soon began at their facilities in Germany.

According to Machhammer, the partnership was a huge success. “An innovative and promising technology was transformed into a commercially viable solution,” he points out. “This opens up opportunities for the whole automotive industry when it comes to reducing weight and improving safety.”

After production volume ramps up at Lucid’s new assembly plant in Casa Grande, AZ, Fischer plans to open a nearby facility to produce aluminum parts.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!