Home » Keywords: » resistance welding

Items Tagged with 'resistance welding'

ARTICLES

Optimizing the Spot Welding Process

Spot welding can be improved in many ways, starting with selecting the right machine, maintaining heat balance and using advanced controls.

April 13, 2021

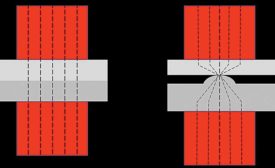

Resistance Projection Welding

For joining dissimilar materials, resistance projection welding offers cost-saving options

April 5, 2018

Joining Wire to Small Metal Parts

State-of-the-art welding and soldering equipment ensure that wires are securely joined to terminals or other wires.

July 5, 2017

Vision-Guided Robots Improve Nut Welding

Machine vision lends flexibility to robotic welding cell

November 3, 2014

Get our new eMagazine delivered to your inbox every month.

Stay in the know on the latest assembly trends.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing