Home » Keywords: » lightweight vehicle structures

Items Tagged with 'lightweight vehicle structures'

ARTICLES

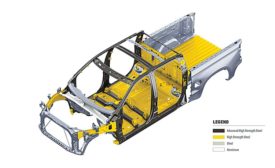

New Techniques for Joining Steel and Aluminum

Lightweighting is forcing automotive engineers to explore cutting-edge technology.

April 11, 2017

Get our new eMagazine delivered to your inbox every month.

Stay in the know on the latest assembly trends.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing