Originally developed by NASA for the space program, fuel cell technology is under commercial development as a method of delivering clean, efficient electrical power to commercial, industrial and residential customers.

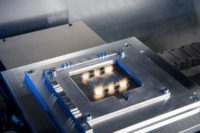

"Fuel cell plates are a critical part and major cost in the design of modular fuel cell systems," says Mark Bahmueller, vice president of Hull/finmac. "The technology requires that the plates have high conductivity, no permeability, and high strength characteristics with minimal thicknesses."

The challenge was to develop a high-yield method for repeatably molding the plates from a thermoset compound with high density, high conductivity and low weight. To solve the problem, the Hull/finmac researchers developed a series of fast-acting automatic compression presses with closed-loop control and a deflashing system. To date, the new compression molding system has yielded optimum results with all of the various thermoset compounds used to make the plates.

For more information, call 215-441-8163 or visit www.hullcorp.com.