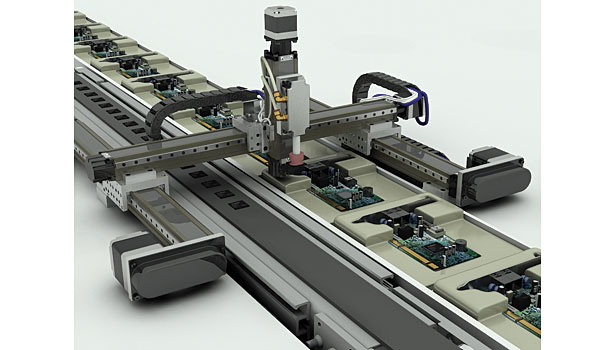

Speed is essential for high-volume assembly. However, speed also creates problems.

In a pick-and-place operation, for example, moving quickly from side to side and stopping on a dime sets up vibrations. To pick or place a part with any kind of accuracy, the machine must pause, even for just a fraction of a second, until the vibrations stop. That’s known as settling time, and in a high-volume operation, those milliseconds can add up.

Consider a short pick-and-place operation, 200 millimeters across, 100 millimeters down, and back. Each horizontal move takes 0.5 second with a settling time of 0.05 second, and each vertical move takes 0.2 second with a settling time of 0.05 second. That translates to 1.6 seconds per part, 37.5 parts per minute or 2,250 parts per hour. If each part is worth $0.1, the operation is producing $225 in revenue per hour.

If settling time can be reduced from 0.05 to 0.004 second, that same pick-and-place operation now takes 1.416 seconds. That translates to 42.37 parts per minute or 2,542 parts per hour. Now, the same operation is generating revenue of $254.24 per hour—$29.24 more. In a two-shift operation running six days per week, saving just 0.184 second in settling time translates to $140,353 in additional revenue per year!

Automation engineers can address the problem of vibration and machine resonance in several ways. Mechanically, they can design a machine with robust components, tight tolerances and minimal backlash.

“In general, you want the motor to be coupled as closely and tightly to the load as possible,” explains Scott Carlberg, product marketing manager with the Drives and Motion Div. of Yaskawa America Inc. “You want to minimize mechanical compliance in your system. Any moving part between the motor shaft and the load, such as a coupling or gearbox, causes compliance. All those components are susceptible to heat, friction, and wear and tear.”

Engineers can also address the problem electronically through the amplifier in a servo-driven system.

Filters are one way to do that. Low-pass filters attenuate vibrations between 1,000 and 5,000 hertz. Notch filters control vibrations between 500 and 1,000 hertz.

“The problem with filters is that they put a ceiling on your bandwidth,” says Carlberg. “That limits how tightly you can tune the system.”

Another way to address the problem is through vibration suppression. Yaskawa’s Sigma-5 servo amplifier features a unique algorithm for just that. The algorithm can suppress vibrations of 50 hertz or less without compromising bandwidth.

The key is the 20-bit, high-resolution encoder coupled to the servomotor. With more than 1 million counts per rotation of the motor shaft, the encoder can detect even small vibrations transmitted through a belt or ballscrew.

“The algorithm takes speed and torque signals from the encoder and adjusts the command signal for the motion,” says Carlberg. “Say you’re commanding a regular trapezoidal profile—accelerate, run at a certain speed, and then stop. The amplifier will follow that commanded motion as tightly as possible. But, during the move, all kinds of vibration will try to push the motor off its path. The vibration suppression algorithm knows the wave form of that vibration and adjusts the command signal in the opposite direction, essentially cancelling it out.”

Suppressing vibration dramatically reduces settling time, which translates into greater throughput. It also enables engineers to design smaller, lighter weight mechanisms, which lowers the overall cost of the machine.

“Less vibration also means less wear and tear on the machine,” adds Carlberg. “Your machine will run more smoothly and quietly, and ultimately, it will last longer.”