Origin Technologies Corporation receives many inquiries about our LaserGauge® product line. Most of the questions from prospects start with “I want to measure XYZ but I am not sure what sensor I need”. With that in mind, we have provided some insight and thoughts to help you select the proper sensor for your particular application.

What industry are you in?

Our tools are used in many different industries, from automotive to aerospace to metal forming to medical devices to heavy steel to many others. Each industry has specific needs which we address with our sensors and accessories.

What type of feature do you want to measure?

This allows us to narrow the applicable tools to the proper field-of-view (FOV) and depth of focus. Are you measuring welds, part alignment, angles, contours, pitting, corrosion, fretting, wear, radii, gap/flush, scratches, fastener height, rivets, step, blade leading/trailing edge, etc. Our sensor are available in FOV from 0.25” for high resolution and accuracy of 0.00025” capable of measuring the smallest features up to a FOV of 3.3” for large features.

What is the surface made of? Is the surface curved or flat?

We have new blue laser-based sensors that can be used for measuring features on transparent or opaque surfaces for use around headlights, taillights, chrome, etc. Our red laser-based sensors are perfect for most other metal or solid plastic surfaces. All our sensors work on flat surfaces or those with complex curves.

What are the nominal measurements and what accuracy is required?

What method/tools are you currently using?

Different FOV and resolution will provide different levels of accuracy. Our Virtual Gauges have flexible configuration parameters that allow the user to configure the sensor and gauges so that it returns measurements consistent with your specified measurement methodology.

What type of environment will the sensor be used in?

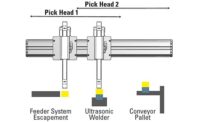

The LaserGauge product line features products and accessories for a wide range of user environments. If you have operators measuring gap/flush on a moving assembly line, sensors need to be handheld, wireless, portable and fast. If you need an end-of-arm solution for your automation system, we can help. We also offer benchtop systems with bigger display screens and AC power.

What is your budget and acquisition timeframe?

What are the budget requirements and particular schedule demands that you must meet?

Can you send me some sample parts?

After discussing the above requirements with your Origin Technologies Corporation representative, the next step is acquiring sample parts from the prospect (if possible). This allows us to use ALL our solutions to determine the exact model sensor(s) and Virtual Gauge to return the measurements that best meet your requirements, ensuring the best solution.

Being prepared to discuss these questions can provide a better idea of which of our many solutions would be the best sensor for your needs.