BROOKLYN, NY—Voodoo Manufacturing has launched Voodoo Clear Aligners, a new dental manufacturing and distribution service, for its first partnering direct-to-consumer brand Smilelove, and expanded its high-volume 3D printing factory here. The addition of Formlabs 3D printers will enable Voodoo to manufacture and ship more than 20,000 unique orthodontic clear aligners each month in the near future.

Making dentures traditionally is a very high skill, labor-intensive profession. Thus, efficiencies and affordability gained through digital workflows and 3D printing allow for better care and accessibility to treatment. Various additive manufacturing techniques such as stereolithography, mask stereolithography and digital light processing have been explored for the production of clear aligners.

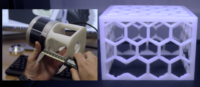

Voodoo Clear Aligners produces and distributes 3D-printed clear orthodontic aligners for direct-to-consumer brands. Through high-resolution 3D printing, Voodoo’s molds are reportedly highly accurate with barely visible layer lines and minimal print artifacts. Moreover, full customization is enabled through Voodoo’s precision robotic trimming process.

To ensure every device is 100 percent traceable, Voodoo laser marks a unique alpha-numeric code on every single aligner. Step numbers and the brand’s logo can also be added upon request. On top of pursuing product perfection, Voodoo stresses on streamlined and customer-friendly service. Rather than having the company repackage the aligners, Voodoo packs aligners in its client’s custom packaging and drop-ship them directly to its patients.

Voodoo promises to fulfill orders in five days or less, compared to the industry average turnaround time of three weeks.

Voodoo Manufacturing Expands 3D-Printing Factory