All liquids change viscosity as a function of temperature—even water. As the temperature increases, the viscosity decreases. Conversely, when the temperature decreases, the viscosity increases.

The viscosity of an adhesive can range from 200 to 1.5 million centipoise (cps). However, that viscosity will vary, depending on the temperature. For example, one sealant’s viscosity drops steeply from more than 8,000 cps at 64°F to less than 4,000 cps at 78°F—a twofold decrease in viscosity in a span of just 14 degrees.

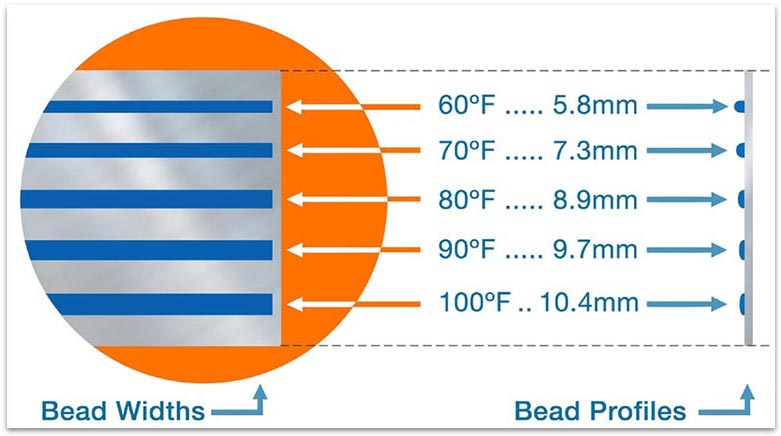

Temperature-related variation in viscosity can directly affect the shape of the bead or fan pattern being dispensed. Photo courtesy Saint Clair Systems

“Even small variations in the temperature of an adhesive and sealant will produce large changes in viscosity, and that can have a significant effect on the performance of the dispensing process,” says Mike Bonner, vice president of engineering and technology at Saint Clair Systems in Washington, MI.

Saint Clair specializes in technology for controlling material viscosity in a variety of industrial processes, including printing, painting, coil coating, overmolding and adhesive bonding. Since 1990, the company has supplied more than 3,600 temperature control systems around the world.

The company’s technology is important for bonding, because temperature-related variation in viscosity can directly affect the shape of the bead or fan pattern being dispensed. For example, if a hem flange sealant is thinner than expected, the bead might be wider and flatter than specified. This is often referred to as spread or slump. It can significantly compromise the function of the bead.

If the adhesive is being dispensed manually, a skilled operator can often compensate for such variation through hand-eye coordination. That’s not an option with a robot, says Bonner. Robots are designed to dispense adhesive along the same path, at the same speed, at the same height and angle, and at the same volume and flow rate, cycle after cycle. They can’t compensate for viscosity variations resulting from changes in ambient temperature that occur from morning to evening or season to season.

This was the case at the Tata Motors assembly plant in Pune, India. Tata Motors is India’s third-largest manufacturer of passenger vehicles. Every seventh car sold in India is made by Tata Motors.

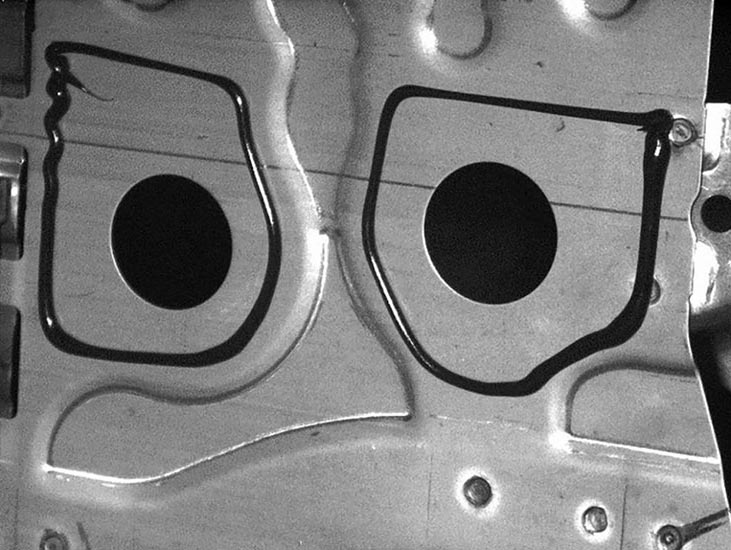

If a sealant is thinner than expected, the bead might be wider and flatter than specified. This can significantly compromise the function of the bead. Photo courtesy Saint Clair Systems

The Pune factory was experiencing frequent and unpredictable line stoppages resulting from dispense pressure faults in the body shop sealer cells. Carmakers typically apply sealer along the edges of sheet metal assemblies, such as door panels. This is done to prevent corrosion and improve stiffness, crash durability and fatigue performance.

Analysis of Tata’s sealer system showed that the pressure drop in the distribution piping was varying due to temperature-related changes in sealer viscosity. This was related to both day-to-night and season-to-season temperature fluctuations.

To solve the problem, Saint Clair Systems deployed a system using its traced cover and coaxial hose technologies to isolate the distribution piping from ambient influences and control the temperature of the sealer along its path, all the way to the point of dispense.

Controlling the temperature of the sealer at all points in the system stabilized sealer viscosity. This provided multiple benefits:

- A stable pressure drop profile in the distribution system, which eliminated line stoppages due to pressure faults and provided a constant, repeatable pressure at the applicator.

- A stable viscosity at the applicator nozzle, which resulting in controlled, consistent and repeatable dispense quality.

- Reliable system operation independent of environmental temperature fluctuations.

Saint Clair’s temperature control units maintain the desired temperature of an adhesive to ±1°F at the point of application. Temperature control units are self-contained systems. Expandable by controller to communicate to any line configuration, thermal sizing tools ensure that the capacity of a temperature control unit is just right.

For more information on viscosity control technology, visit Saint Clair’s website at https://viscosity.com.

ASSEMBLY ONLINE

For more information on automated dispensing, read these articles:

Dispensing Thick Materials

Troubleshooting the Dispensing Process

Dispensing with Six-Axis Robots