DFMA Assembly

Assemblers are busier than ever, thanks to the U.S. manufacturing revival.

Read More

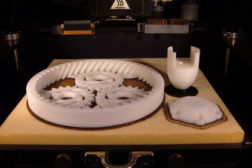

BYU Engineers Push Product Design Boundaries

Traditionally, automobiles, lawn mowers, airplanes, dishwashers and other products contain a wide variety of rigid parts connected by joints that are designed to be strong and stiff.

May 1, 2013

DFMA — A Potent Lean Methodology

With its emphasis on simplifying designs and standardizing parts, DFMA can help manufacturers get lean.

April 1, 2013

Get our new eMagazine delivered to your inbox every month.

Stay in the know on the latest assembly trends.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing