A designer and manufacturer of electrical components, Jiangsu Phono Electrical Co. Ltd. faces the ongoing challenge of creating high-quality and safe products at the lowest cost. Based in Zheng Jiang, China, the company makes many products, including molded-case circuit breakers (MCCBs).

MCCBs operate at much higher electrical ratings than residential circuit breakers. They also isolate electrical paths and protect downstream equipment from overloads. These benefits—in conjunction with the need for companies to conserve energy—have led to increased use of MCCBs in industrial and commercial applications.

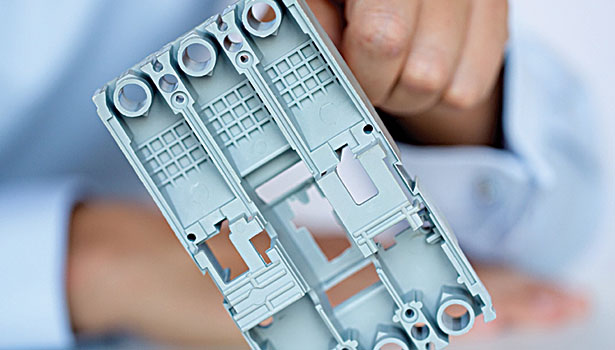

The breakers feature a heavy-duty molded plastic case with open arc extinguishing chambers. Each chamber has several functioning internal components.

For a long time Jiangsu made MCCBs out of thermoset bulk-molding compounds. However, the company often received requests from customers for breakers with more electrical endurance, better aesthetics and thinner cases.

Jiangsu researched the use of alternate materials to meet these requests. Eventually, the company came across Stanyl, a high-performance polyamide 46 made by the global material sciences company Royal DSM. For the last several months, Jiangsu has been making the breaker case and internal chamber components out of this material.

“We were impressed by DSM’s knowledge of this application and its willingness to innovate together with us,” says Jiang Changsheng, general manager at Jiangsu Phono. “Plus, the company offers us continuous support and advice.”

Changsheng says the polyamide enables the MCCBs to have thinner cases, yet achieve electrical endurance ratings of up to 100 kiloamps with 400 volts. He notes that the polyamide also lowers production cost by 10 to 15 percent and makes the breakers recyclable.

Stanyl retains its mechanical properties at temperatures up to 230 C over the long term. It offers excellent stiffness at elevated temperatures, as well as extended fatigue endurance. The polyamide also provides low friction, and excellent wear and abrasion resistance for moving parts.

For more information on polyamides, call 248-792-9136 or visit www.dsm.com.