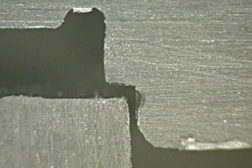

Plastics & Metal Welding Assembly

The Benefits of Servo-Driven Ultrasonic Welding

Servo-driven ultrasonic welders can match welding speed to the melt flow rate of the plastic.

November 1, 2013

Get our new eMagazine delivered to your inbox every month.

Stay in the know on the latest assembly trends.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing