Home » Keywords: » dispensing equipment

Items Tagged with 'dispensing equipment'

ARTICLES

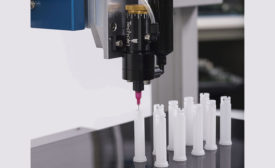

New Technology for Micro-Dispensing

Noncontact jetting offers distinct advantages over needle-based technology for micro-dispensing applications.

October 19, 2017

Adhesive Dispensing & Curing

New Dispensing, Curing Technology Improves Productivity

February 9, 2016

EVENTS

Webinar Webinar

1/31/24 to 1/31/25

Contact: Meg K.

Manufacturing Investment 2023-2024: Looking Back, Looking Forward

Get our new eMagazine delivered to your inbox every month.

Stay in the know on the latest assembly trends.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing