Home » Keywords: » delta robots

Items Tagged with 'delta robots'

ARTICLES

Robotics

Cartesian, SCARA, Six-Axis and Delta: Robots Wowed Crowds at The ASSEMBLY Show

January 13, 2017

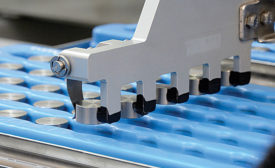

Additive Manufacturing and End Of Arm Tooling

Innovative 3D-printed end-of-arm tooling enables systems integrator to lighten the load on a robotic packaging line.

July 1, 2016

Get our new eMagazine delivered to your inbox every month.

Stay in the know on the latest assembly trends.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing